Do you need to know how a circuit breaker works to fly airplanes? No. But if something goes wrong, this bit of knowledge will prepare you to weigh the decision: "should I reset that breaker?"

— James Albright

Updated:

2019-04-24

Not everything here is from the references shown below, with a few comments in green. Not everything? The inner workings of a traditional thermal circuit breaker appear to be "old news" and I've not found anything definitive about them.

1

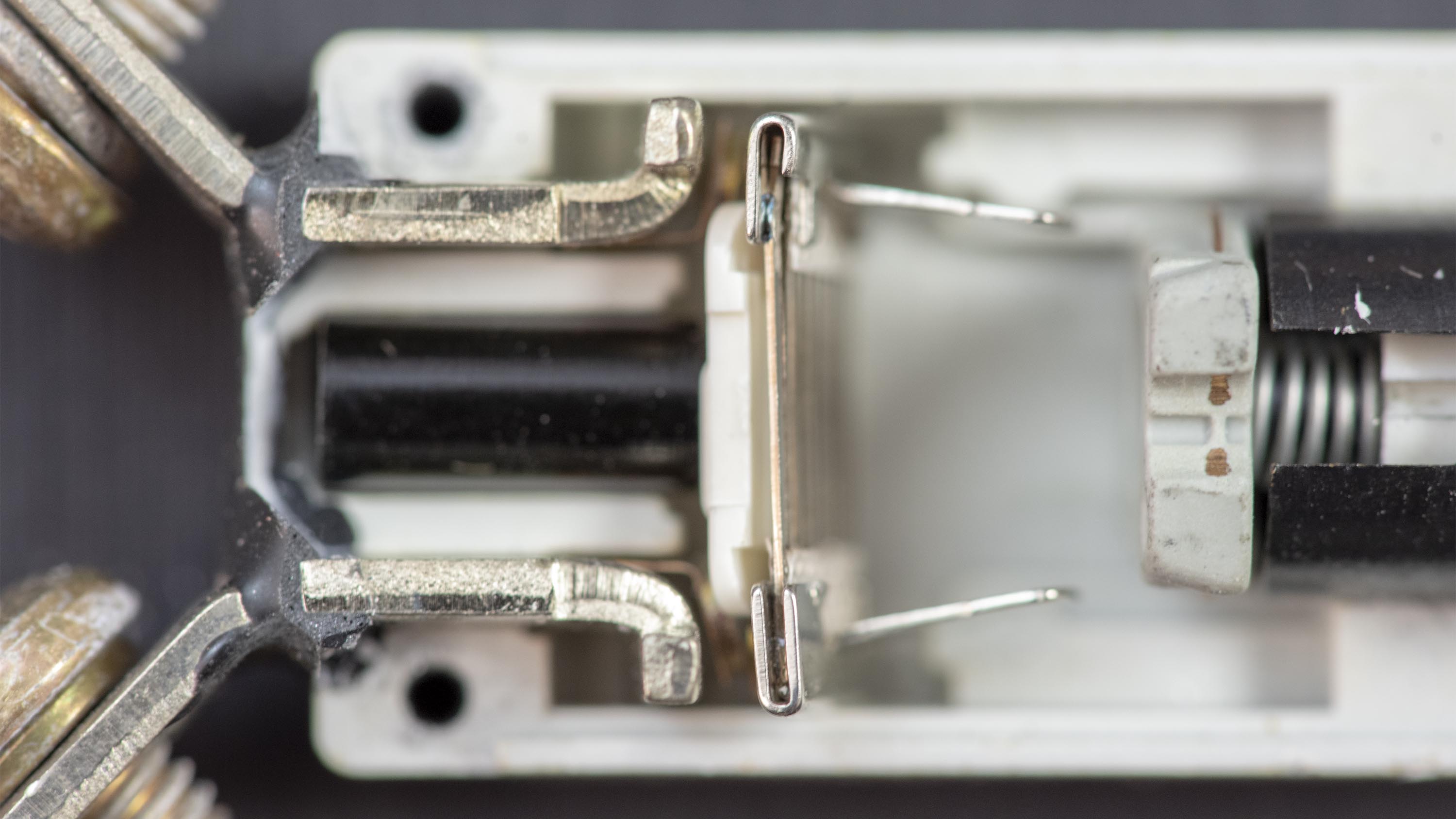

How a typical thermal circuit breaker works

I've seen other designs but this appears to be typical for an aircraft circuit breaker. They key point is that the metal disc inside the CB gets hot. When it gets too hot, it trips. Repeatedly resetting the breaker, or worse yet, holding it in, increases the heat. The result can be a breaker with the metal disk broken so it won't reset or fused shut so it won't reopen.

The "How"

A thermal circuit breaker is designed to repeatedly interrupt short circuits or overloads. Current is passed through a metal strip which bridges two metal contacts. The strip is designed in an arc which will suddenly snap into a reverse shape at a certain temperature. A secondary thermal disc, or the strip itself, heats up below a critical point if the current remains below its trip point. Above that point the strip snaps and the two contact points are no longer bridged. Once popped, the metal strip must be allowed to cool before it can be reset. To reset, a button pushes the outside of the metal strip to snap it back into its original shape.

The Problems With This

Because the thermal circuit breaker depends on heat, the ambient temperature can affect the resulting trip point. There are a lot of parts in these circuit breakers which can be impacted by corrosion. Old circuit breakers can fail in either direction. If failed open, you know you have a problem. If failed closed, the circuit breaker fails to pop and you've lost any protection you had been counting on. There is also the issue of a "brute force" reset. You can lean on these types of circuit breakers and force them closed.

Is it a switch? How often can you reset?

A number of years ago it wasn't a big deal to have a circuit breaker pop, count to three, a push it back in. Over and over again. Here is what many Boeing 707 manual had to say about this back in the seventies:

The circuit breaker affords a good means of circuit protection against high current loads. All circuit breakers are of a trip-free design; that is, they cannot be manually held in to override the circuit breaker and force it to remain in a reset position. Heating of a bimetallic strip causes the actuator to trip: therefore, after a circuit breaker has been tripped, it must cool before it can be reset. The cooling time required before reset can be accomplished is approximately 3 seconds. Circuit breakers may be pulled and reset without damage to the circuit breaker; however, circuit breaker pulling should be kept to a minimum as switches are provided to cut the power to electrically powered equipment.

Source: 1C-135(E)C-1, p. 1-57

Another manual limited us to 3 resets. But after more than a few times where that didn't work out, most manufacturers have gravitated to the "thou shalt not" theory of circuit breaker resetting:

- In flight, flight crew reset of a tripped circuit breaker is not recommended. However, a tripped circuit breaker may be reset once, after a short cooling period (approximately 2 minutes), if in the judgment of the captain, the situation resulting from the circuit breaker trip has a significant adverse effect on safety. On the ground, flight crew reset of a tripped circuit breaker should only be done after maintenance has determined that it is safe to reset the circuit breaker.

- Flight crew cycling (pulling and resetting) of a circuit breaker to clear a non-normal condition is not recommended, unless directed by a non-normal checklist.

Source: B-777 FCOM, §CI.2.4

FAA Guidance

- Resetting Circuit Breakers in Flight.

- Potential Hazards Associated with Tripped Circuit Breakers. The FAA has published guidance material that states that circuit breakers are slow-acting devices and may not offer sufficient disconnect protection during events such as arc tracking or insulation flash-over. Arc tracking is a phenomenon in which a conductive carbon path forms across an insulating surface. The carbon path provides a short circuit path through which current can flow (e.g., electrical arcing). The effects of electrical faults can include:

- Component overheating;

- Toxic fumes;

- Fire;

- Damage to wires, wire bundles, or parts;

- Melting of holes in sheet metal parts by faulted, high-current feeder cables;

- Melting and burning of titanium bleed air ducts by a chafed, high-current feeder

- Electromagnetic interference (EMI) with equipment; and

- The simultaneous and unreasonable loss of both engine-driven generators in a two-engine airplane.

- Using a Circuit Breaker as an On/Off Switch. Since circuit breakers are designed to open an electrical circuit automatically at a predetermined overload of current, they should not be used for day-to-day operational functions because they would not be performing their intended function, which is protection against overloads. You should not use circuit breakers, even those suitable for frequent operation, as a switch to turn protected items on or off. An air carrier should publish and include in its approved maintenance programs and flight operations manuals any exceptions to this procedure.

(1) The FAA reiterates its concern about resetting circuit breakers during flight. Crewmembers may create a potentially hazardous situation if they reset a circuit breaker without knowing what caused it to trip. You should not reset a tripped circuit breaker in flight unless doing so is consistent with explicit procedures specified in the approved operating manual used by the flightcrew or unless, in the judgment of the captain, resetting the circuit breaker is absolutely necessary for the safe completion of the flight. A detailed entry in the aircraft’s maintenance log is a proven safety practice for tracking purposes, and may provide maintenance personnel with key information to enable prompt troubleshooting and effective corrective action on the ground.

(2) Air carrier manuals and training programs should contain company policies and explicit procedures regarding resetting tripped circuit breakers, both during flight and on the ground. The procedures shown in the manuals used by the air carrier’s crewmembers, maintenance personnel, and airplane ground servicing personnel should be consistent with the airplane manufacturer’s guidance. You should remind crewmembers not to use a circuit breaker as a switch to perform procedural functions unless doing so is specified in approved company procedures or manufacturer’s operating procedures.

NOTE: The current edition of AC 25-16, Electrical Fault and Fire Prevention and Protection, contains additional information about this subject.

Source: AC 120-80A, ¶16

What can go wrong

On June 2nd, 1983, an Air Canada DC-9 was destroyed and 23 of 46 passengers were killed as a result of a cabin fire. Three circuit breakers associated with an aft lavatory popped and the captain, according to policy at the time, attempted to reset all three. At point he noted that the breakers "pops as I push it." The fire wasn't traced to the lavatory flush motors but that a generator feeder cable could have been the culprit. The NTSB was unable to identify the source of the fire but industry philosophy on circuit breakers was forever changed. More about this: Case Study: Air Canada 797.

2

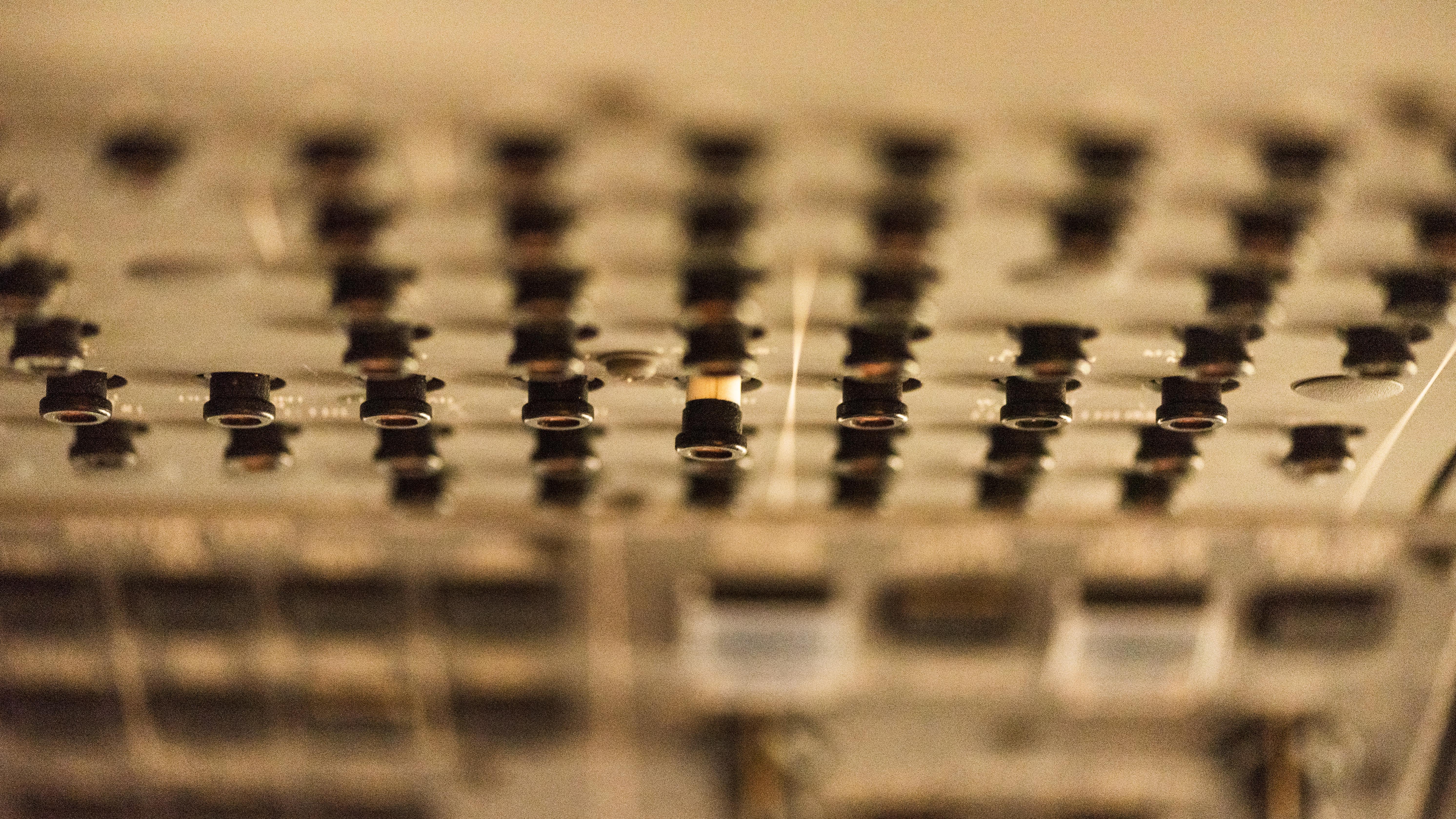

How a solid state circuit breaker works

As we have seen, a hardware circuit breaker has a time lag between excess current and the tripping of that current. It also suffers from accuracy since it relies on the temperature of the breaker itself. Finally, the hardware is subject to corrosion and age effects. If you replace the hardware, you can get rid of those problems. A solid state circuit breaker offers a solution.

We in aviation are used to reading schematics where lines representing wires go into squares representing electrical components. In the old days you could rationalize what was happening in that box. But in the day and age of computers, you might as well write "magic happens" on that box. We are expect to read what happens and believe it. "Trust us." When it comes to solid state circuit breakers, you are left wondering how does the current get switched off without a switch?

What follows is a forty-year old recitation of a failing memory of two years of electrical engineering classes. But for the purpose of understanding your virtual circuit breakers, I hope this helps.

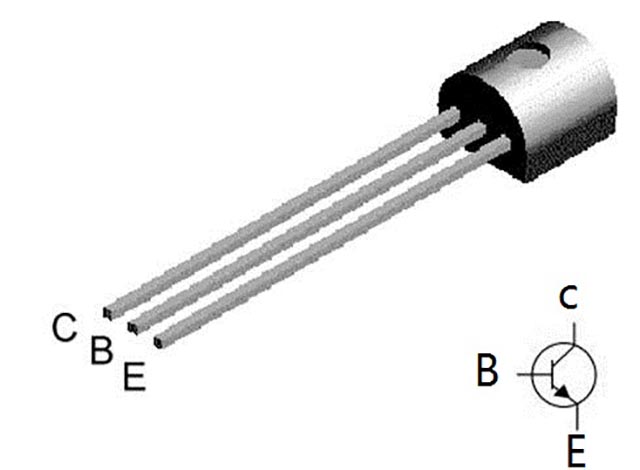

- A transistor is manufactured by sandwiching two types of silicon that react to electricity in different ways.

- In the diagram above, you have a [C]ollector, [B]ase, and [E]mitter.

- There are different configurations, but one possible configuration is to have the current pass from the Collector to the Emitter. Depending on how you choose the types of silicon, you can have the transistor allow the flow of current from the Collector to the Emitter if the current in the Base is low or high.

- When wired suitably, you can build a circuit breaker with no moving parts.

- And this circuit breaker also makes a switch with no moving parts. If you give other parts of the airplane access to [B]ase, they can switch the circuit on or off for you.

More about Bipolar Junction Transistors: https://oscarliang.com/bjt-bipolar-junction-transistor-beginner-tutorial/.

References

(Source material)

Advisory Circular 120-80A, In-flight Fires, 12/22/14, U.S. Department of Transportation

Boeing 777 Flight Crew Operating Manual, July 18, 1995

Technical Order 1C-135(E)C-1, EC-135C Flight Manual, USAF Series, 15 February 1966