We used to say our GV made fuel on long trips and a lot of GV pilots believed that for many years. Our AFM procedure was to "zero" the FMS fuel quantity every hour, that is, we would make the FMS fuel quantity agree with the tank quantity. We would also check the FMS predicted arrival fuel every hour. Sometimes, but not for every flight, the FMS fuel quantity every hour seemed to be a bit low. Sometimes, but not for every flight, the predicted fuel quantity seemed to increase steadily as the flight progressed. The airplane, it seemed, was making fuel.

— James Albright

Updated:

2015-04-16

Say what you will about the Gulfstream engineering types, they are very good about investigating these mysteries. They found the culprit. If the temperature of the fuel in the tank was appreciably different than the fuel truck, and large onload of fuel would result in fuel stratification. There would be a layer of warm fuel on top of cold fuel and that fooled the capacitance probes into thinking there was less fuel than actual. More about this: Fuel Capacitance Probes.

What follows comes from an undated, unsourced, document from Gulfstream. They don't publicize this or in any way seem to take credit for it. You really have to dig for it, but here it is. They included a PDF worksheet that helps you figure out how much fuel you really have. In actual practice, it is a bit cumbersome. But if you want it, here it is: interact_g5_fuel_stratification_rev1.pdf.

When an aircraft is refueled soon after landing from a flight that has been at altitude for several hours, the resulting fuel on board indication may not be completely accurate. The inaccuracy is due to the placement of sensors in the fuel tanks combined with the physical tendency of fuel of different temperatures to separate into layers, or strata. Fuel remaining at the end of a flight is cold soaked, and fills the tank hoppers in each wing since the hoppers are at the low point of the fuel tanks nearest the fuselage. Fuel added during refueling will be at near ambient temperatures and warmer than the cold fuel remaining in the hoppers. The added fuel will therefore be less dense and form a layer (strata) on top of the cold fuel in the hoppers.

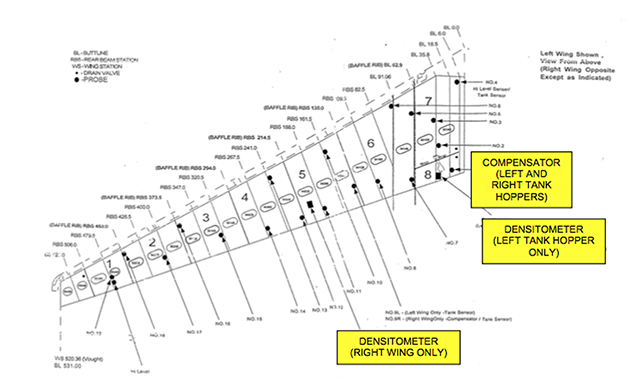

The Fuel Quantity Signal Conditioner uses information from nineteen (19) fuel tank unit array probes in each tank, and from densitometer and compensator sensors placed within the fuel tanks to provide accurate information to the aircraft fuel quantity indications. Densitometers are located in the middle of the right wing near where fueling takes place and in the hopper of the left tank. Densitometers are electromechanical oscillators that vibrate at a frequency proportional to the density of the fuel in which they are immersed. Compensators are located only in the fuel tank hoppers, and calculate the dielectric constant (k) of the fuel surrounding them. The value of (k) is dependent upon the fuel type and constituent additives. Most importantly for this discussion, (k) is also affected by temperature – (k) varies inversely with temperature. See the following illustration of the location of fuel tank sensors:

Since fuel added during refueling is layered on top of fuel remaining in the tank hoppers, inputs from the tank unit arrays, densitometers and compensators are not consistent. The right wing densitometer samples the density of the newly added fuel; however, the tank unit arrays are immersed in a combination of cold remaining fuel and warmer added fuel and the left wing densitometer and the compensators are submerged in cold soaked fuel.

The resulting inaccurate fuel volume measurement is a result of the following formula:

Volume = [CTE(k-1)] (warm fuel)

--------------------------------

[CCE(k-1)] (cold fuel)

Where CTE = Effective capacitance of the immersed tank unit array

CCE = Effective capacitance of the submerged compensator

As stated above, (k) varies inversely with temperature, therefore in the above formula, the value of (k) for the (cold) compensator is more than the value of (k) for the (warmer) tank array – since the denominator is larger, the resulting measured volume is smaller. However, if the aircraft sits on the ramp for a period of time after refueling, the fuel in the tank hoppers will gradually warm, and the temperature differential between the fuel remaining at the end of the flight and the fuel added will be eliminated, the stratification will disappear, and result in the same uniform value for (k) and an accurate reading of fuel volume.

It is difficult to determine exactly the amount of fuel quantity error generated by the stratification phenomenon – the fuel quantity initially indicated is always less than the actual onboard fuel (provided, of course, that the fuel added is warmer that the residual fuel). Instances have been observed when the fuel on board indication is actually 800 to 1200 lbs. low. Several factors influence the fuel quantity reading: the amount of fuel remaining in the hoppers relative to the amount of fuel added, the temperature differential between the two fuel segments, and the time elapsed since the refueling took place. General observations have revealed that after approximately ten (10) hours on the ramp, fuel temperatures are consistent throughout the wing and quantity errors are eliminated.

Crews have observed that if the aircraft is refueled when cold, fuel remains in the hoppers and another flight segment is flown soon after refueling, the aircraft "makes" fuel – that the fuel used as shown on the FMS that uses fuel flow to track consumption will not match the expected indicated amount of fuel on board – for instance, the FMS indicates that the aircraft has consumed 3,000 lbs but the indicated fuel on board has decreased only 2,200 lbs. This discrepancy usually disappears after about one hour of flight when fuel tank temperatures stabilize.

All fight crews should be aware of the stratification issue to avoid any misunderstanding concerning fuel quantity indications and subsequent unnecessary maintenance write ups.

References

(Source material)

Please note: Gulfstream Aerospace Corporation has no affiliation or connection whatsoever with this website, and Gulfstream does not review, endorse, or approve any of the content included on the site. As a result, Gulfstream is not responsible or liable for your use of any materials or information obtained from this site.