There were two notable crashes of Boeing 757s in 1996, both due to their pilots’ inability to understand seemingly nonsensical airspeed or altitude indications. Many pundits will tell you that the 757 manual didn’t have a procedure for “unreliable airspeed” or “airspeed disagree” indications back then, but that isn’t true. The 757/767 QRH as far back as 1990 had such procedures. They will also tell you the behavior of pitot/static systems when blocked wasn’t understood back then. Again, that isn’t true.

— James Albright

Updated:

2025-10-15

In the 1930s and 1940s, the Royal Air Force and the Luftwaffe had several training accidents due to pitot tubes obstructed with ice, resulting in stalls leading to crashes. In the 1950s, the USAF added to these with accidents in the T-33 trainer and several fighters. There were also two BOAC Comet test and training flights where the aircraft wasn’t lost, but the effect of icing was well documented. In the 1960s, Air France Flight 117, Eastern Airlines Flight 304, and Pan Am Flight 212 were all lost to pitot/static blockage. I got my Air Force pilot wings in 1979, and pitot/static blockage recognition and recovery was taught.

All those examples aside, there is no doubt it can be confusing when one of your airspeed indicators isn’t working for a time and then it is. It is awfully tempting to think the problem is fixed. But understanding three pieces of information can save you:

- A blocked pitot tube behaves like an altimeter, as altitude increases so does the displayed airspeed.

- If you have three altimeters using different pitot/static systems, the standby system is often the “tie breaker.” Go with the majority.

- Even with no reliable airspeed or altitude information, you can still maintain aircraft control by using known pitch and thrust settings.

There may be no better illustration of these concepts than the Case of Birgenair 301.

Date: February 6, 1996

Time: 0745Z

Aircraft: Boeing 757

Registration: TC-GEN

Operator: Birgenair

Departure Airport: Gregario Luperón International Airport (MDPP), Puerto Plata, Dominican Republic

Aircraft fate: destroyed

Fatalities: 176 of 176 passengers, 13 of 13 crew

1 — The last minute schedule change

2 — The aircraft’s extended ground time

3 — Pilot qualification and training

4 — Flight sequence from takeoff to initial climb

5 — Airspeed indicator fundamentals

6 — Flight sequence from initial climb to stick shaker

1

The last minute schedule change

On February 6, 1996, a charter flight operated by Airline Alas Nacionales was scheduled to fly from Gregario Luperón International Airport, Puerto Plata, Dominican Republic, to Europe, with a planned departure time of 0500Z (0100L). About 2-1/2 hours prior to departure, the planned aircraft, a Boeing 767 was canceled due to a mechanical problem. The aircraft operator, Birgenair, had a Boeing 757 available, but it had been sitting on the ground for 20 days. It took a while to get the aircraft ready and to scramble a new crew. The new crew minus one flight attendant reported to the airport at 0615Z (0215L), the remaining flight attendant an hour later, and the aircraft finally took off at 0742Z (0342L).

2

The aircraft’s extended ground time

The aircraft had not been flown for twenty days prior to the accident flight.

During this period, an engine inspection was performed that required an engine ground test before the next takeoff. Investigators believe that the engine and pitot covers were not installed before or after the engine ground test.

The subsequent analysis of the cockpit voice recorder (CVR) and the flight data recorder (FDR) revealed that there was no initial indication on the captain's airspeed indicator, but during the aircraft's ascent it began presenting inaccurate information due to an obstruction of the left upper pitot tube. The exact reason for the obstruction of the pitot tube was never determined.

However, the authorities of the investigation concluded that the probable source of obstruction in the pitot system was mud and/or debris from a small insect that was introduced in the pitot tube during the time the aircraft was on the ground in Puerto Plata.

In spite of the fact that the aircraft remained on the ground and was not flown for twenty (20) days before the crash, the aircraft was returned for service without a verification of the pitot static system as recommended by the manufacturer's maintenance procedures. If this inspection had been completed as a part of the return to service, it may have discovered the blocked pitot tube system and it would have been corrected before the flight.

Source: Accident Report, pp. 19 – 20.

Investigators believe the “Black and Yellow Mud Dauber” was the culprit. These insects are notorious for building their nests quickly in crevices, cracks, or holes to lay single eggs.

The 757 has two independent sets of pitot static systems and air data computers, as well as an independent standby altimeter and airspeed indicator which display raw data. All three pitot tubes are vulnerable to obstructions. They are mounted so high, 8 feet above the ground, they cannot really be checked for blockage from the ground wihtout a ladder.

3

Pilot qualification and training

The captain was a 62-year-old Turkish national, had nearly 25,000 hours on which nearly 1,900 hours was in type, and was the pilot flying. The first officer was a 34-year-old Turkish national, had only 3,500 hours, 71 hours in type, and was the pilot monitoring. The Relief Captain was a 51-year-old Turkish national, had 15,000 hours but only 121 hours in type, and occupied the jump seat for takeoff.

Pilot training was contracted out to vendors in the United States. The captain had been most recently trained at the United Airlines Flight Training Center. The relief captain’s most recent training was at the Pan Am International Flight Academy. The crews had not been required to attend CRM training and had not done so.

Note: this information was extracted from the Accident Report, pp. 7 – 9.

4

Flight sequence from takeoff to initial climb

When they taxied out it was very dark, with the moon sometimes showing through a 7,000 ft cloud base and light rain.

0342:09 Captain: “EPR select”

0342:10 First officer: “EPR, Power’s set”

0342:18 Captain: “OK, checked”

0342:23 First officer: “80 knots”

0342:24 Captain: “Checked”

0342: 26 Captain: “My airspeed indicator’s not working”

0342:28 First officer: “Yes? Yours not working?”

0342:30 First officer: “One twenty”

0342:32 Captain: “Is yours working?”

0342:32 First officer: “Yes, sir”

0342:33 Captain: “You tell me”

Source: Accident report, pp. 24 – 25.

The “80 knots” call is significant for two reasons. First, it is a chance to crosscheck the airspeed indicators. Standard Operating Procedure (SOP) would be to abort the takeoff if the indicators do not agree at this point. It is also significant because it divides the low and high-speed regions of the takeoff. For most operators, aborts are recommended above 80 knots and below V1 for engine failures, fire, loss of directional control, windshear, blocked runway, or other events that make it unsafe to fly. Notice the first several reasons are cut and dried, while the “unsafe to fly” reason is subjective. Three seconds elapsed after the 80 knots call and when the captain realized his airspeed indicator wasn’t working. Just four seconds later, they were accelerating passed 120 knots.

These seven seconds of indecision pushed the decision well into the high-speed portion of the takeoff. In my opinion, rejecting the takeoff in this situation would have been valid any time before reaching V1. Having a reliable airspeed indicator is vitally important and at this point, they aren’t sure how reliable the standby indicator is. It would have been SOP to reject the takeoff as soon the “not working” announcement was made. But that didn’t happen. Two seconds after his “You tell me” call, the captain was committed.

0342:35 First officer: “Vee one, Rotate”

0342:43 Captain: “Positive climb, gear up”

0342:43 First officer: “Positive climb”

0342:44 Cockpit Area Microphone: (Sound of landing gear handle moving)

0342:46 First officer: “Gear is up”

0342:50 First officer: LNAV?”

0342:51 Captain: “Yes, please”

Source: Accident report, p. 25.

All indications are that the captain’s airspeed was frozen during the takeoff run and that the captain rotated to the attitude commanded by his flight director. Just nine seconds later, the captain believes the problem has resolved itself:

0343:00 Captain: “It began to operate”

Source: Accident report, p. 25.

5

Airspeed indicator fundamentals

The displayed airspeed for each pilot in the Boeing 757 is filtered through an Air Data Computer (ADC). Pilots of these types of modern aircraft have become used to pitot-static systems that rarely fail. When I started flying jets in 1979, some of our aircraft only had one airspeed indicator which was nothing more than a single pitot tube, a static port, copper tubing, and an indicator. Having them not “just work” all the time was something we trained for. Perhaps all modern-day pilots should review some procedures from basic flight training.

A basic airspeed indicator (From my first instrument flight manual, Air Force Manual 51-37, 1976, figure 1-2)

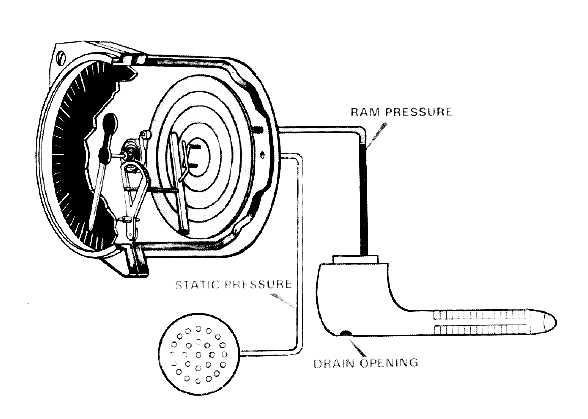

In a very basic system, airspeed is measured by taking the dynamic pressure entering the pitot tube and finding its way to the airspeed indicator where it pushes against a diaphragm which is opposed by the static pressure which comes from the static port through its own set of tubing. In essence: airspeed equals dynamic pressure minus static pressure. A modern system works basically the same way, except the dynamic pressure is fed to the Air Data Computer which converts it to numbers (analog to digital), does the same with static pressure, and then electronically transmits the results. The ADC can also make the necessary corrections so that the pilot sees Calibrated Airspeed (CAS) instead of Indicated Airspeed (IAS).

Now, what happens if the pitot tube is blocked while the airplane sits on the ground? The air in the pitot tube becomes sealed and what is supposed to be dynamic pressure now equals static pressure, which means your IAS = 0. Just what you would expect while stationary on the ground. As you accelerate for takeoff, static pressure hasn’t changed, so IAS is still zero. If one airspeed indicator displays 80 knots and the other display 0 knots during the 80-knot crosscheck, chances are good you have a blocked pitot tube or other problem on one side.

Once you takeoff things change. The static air pressure decreases as you climb and the value that should be dynamic pressure increases because there is less pressure against that diaphragm. In effect, the airspeed indicator has become an altimeter. No wonder the captain of this Birgenair flight exclaimed, “It began to operate.”

6

Flight sequence from initial climb to stick shaker

After the captain’s “It began to operate” call things appeared normal for the next 1 minute and 13 seconds:

0343:02 Captain: Could you turn off the wipers?

0343:03 First officer: Okay, wipers off

0343:08 Captain: Climb thrust

0343:09 First officer: Climb thrust

0343:10 Captain: VNAV

0343:11 First officer: VNAV

0343:16 First officer: Okay, flap speed

0343:17 Captain : Flaps 5

0343:24 Captain: Flaps one

0343:25 First officer: Flaps to one

0343:30 Captain: Gear Handle off

0343:32 First officer: Gear handle’s off

0343:33 Captain: Flaps up

0343:34 First officer: Flaps up

0343:36 Captain: After takeoff checklist

0343:38 First officer: After takeoff checklist, landing gear up and off, flaps are up, checked up, altimeters later, after takeoff completed

0343:47 Captain: Okay

0344:07 Captain: Center autopilot on, please

0344: 08 First officer: Center autopilot is on command

0344:10 Captain: Thank you

0344:12 Captain: One zero one three

0344:13 First officer: One zero one three

Source: Accident Report, pp. 25-26.

At this point, they were climbing through 3,500 feet and were cleared to Flight Level 280. The center autopilot was engaged as well as the Vertical Navigation (VNAV) mode, both of which use airspeed and altimeter data from the captain’s instruments.

The Master Caution Warning system sounded and displayed two messages: “MACH/SPD TRIM” and “RUDDER RATIO.” At the same time, they were cleared to POKEG, a navigation fix. The crew acknowledged the warning messages briefly but then continued with the task of making a course change.

0344:25 Captain: Rudder ratio, Mach airspeed trim

0344:27 First officer: Yes, trim

0344:28 Captain: There is something wrong, there are some problems

0344:43 First officer: Direct Pokeg

0344:44 Captain: Okay, there is something crazy ... do you see it?

0344:46 First officer: There is something crazy there ... right now mine is only two hundred and decreasing, sir

0344:52 Captain: Both of them are wrong, what can we do? Let's check their circuit breakers

0344:55 First officer: Yes

0344:57 Captain: Alternate is correct

0344:59 First officer: The alternate one is correct

Source: Accident Report, pp. 26 – 27.

It is hard to predict what the captain’s airspeed indicator was showing, but given the pitot tube blockage, it was probably increasing and may have even agreed with the first officer’s airspeed at one point. The captain finally noticed that the first officer’s airspeed agreed with the standby airspeed indicator. At this point, the correct move would have been to switch to an autopilot that used the first officer’s instruments and give control of the aircraft to the first officer. The captain, however, did not do this. He talked himself out of the correct analysis:

0345:04 Captain: As the aircraft was not flying and on the ground, something happening is normal. Such as elevator asymmetry and other things. We don't believe them.

0345:23 Jump seat: Shall I reset its circuit breaker?

0345:24 Captain: Yes, reset it

0345:25 Jump seat: To understand the reason . . .

0345:27 Captain: Yeah

0345:28 Cockpit Area Microphone (Sound of overspeed warning)

0345:30 Captain: Okay, it's no matter

0345:39 Captain: Pull the airspeed, we will see...

0345:39 Cockpit Area Microphone (Sound of overspeed warning stops)

0345:40 First officer: Now it is three hundred and fifty, yes

0345:47 Captain: Let's take that like this...

0345:50 Cockpit Area Microphone: (Sound of four warning alert tones)

0345:52 Cockpit Area Microphone: (Sound of stick shaker starts and continues to end of recording)

Source:Accident Report, pp. 27 – 28.

While it is true that lots can go wrong when the aircraft has an extended period on the ground without flying, it was wrong to ignore the correct observation that the standby and first officer airspeed indicators agreed. Pulling the overspeed warning circuit breaker was the right thing to do, given the captain’s airpseed indicator was wrong.

At the time of the accident, there were no identifiable EICAS messages or applicable procedures related to unreliable airspeed. Eight months prior to the accident (June of 1995), Birgenair had added a paragraph to their Flight Crew Training Manual regarding "Flight with Unreliable Airspeed," however, the investigation could not determine if the crew had been briefed or trained on this change. Even if they had, it appears they did not follow the advice. Following the accident, Birgenair added an "Airspeed Unreliable" procedure to their pilot checklist.

Source: FAA Lessons Learned.

Even without an airspeed unreliable checklist, the crew should not have so quickly discounted the fact that two of the airspeed indicators did agree, and those indicators showed the aircraft at a very low speed. The German Federal Bureau of Aircraft Accidents Investigation recreated the accident sequence (available at the FAA Lessons Learned link shown below):

The aircraft pitch was about 15 degrees nose up when the overspeed warning sounded.

The engaged autopilot was using the same information as displayed to the captain and continued to pitch up in an attempt to reduce airspeed.

The captain at this point manually reduced the throttles to about idle.

Source: Luftwaffe video, available at Lessons Learned link.

The pilots should have realized that the stick shaker is an independent source of airspeed information. Because the stick shaker used the Angle of Attack (AOA) indicators, it wasn’t affected by whatever was wrong with the airspeed indicators. Having the stick shaker go off while the overspeed clacker is sounding can be quite disorienting. But the stick shaker was right: the aircraft was approaching an aerodynamic stall. The pilots had the information they needed to correctly assess the situation.

7

Flight sequence from stick shaker to impact

The captain did eventually increase the thrust, but kept the autopilot engaged. The autopilot disengaged itself when it reached its limit of authority. The captain never pushed the nose down. The wings started to rock and the aircraft started descending.

0346:00 Jumpseat: ADI!

0346:07 First officer: Nose down!

0346:31 Jumpseat: ADI!

0346:39 Captain: Not climbing? What am I to do?

Source: Accident Report, pp. 28-29.

The captain had completely lost situational awareness. “What am I to do?” should have been answered with “Recover from the stall!” The jumpseat pilot’s “ADI!” was probably meant to tell the captain his pitch was too high, but in the captain’s confusion, this message was lost. A more appropriate call would have been, “You are in a stall, recover from the stall!”

The lack of airflow caused the left engine to compressor stall, causing the aircraft to roll left. The resulting flight path indicates the aircraft began to enter a spin.

At 03:47:03, at an altitude of 3,520 feet at zero ground speed, a pitch attitude of -53.3 degrees decreasing to -80.0 degrees and a bank angle of -99.8 degrees, power continued to be asymmetrical (EPR L= l.089 R=1.626).

At 03:47:09 the GPWS (Ground Proximity Warning System) began to sound, "WHOOP, WHOOP, PULL UP," at an altitude of 2,368 feet, a pitch attitude of -17.6 degrees and a bank angle of -9.0 degrees. Varying these parameters two seconds later upon impact with the Atlantic Ocean at 14 NM to the northeast of Puerto Plata, with a pitch attitude of -34.3 degrees and a bank angle of -34.6 degrees; all occupants died and the impact resulted in 100% destruction of the aircraft.

Source: Accident Report, p. 6.

8

Lessons

At this point, with the benefit of nearly thirty years of hindsight, the lessons learned may have been codified in many training and operational manuals. The danger with that, however, is that newer generations of pilots who have never seen a pitot-static abnormal situation might think all this is theoretical. It isn’t. Committing the following to memory could someday save you, your passengers, and your aircraft:

- The tie breaker. With three independent pitot-static systems, the two that agree are probably right.

- The reverse altimeter. An airspeed indicator that is frozen at low altitude but comes to life as you climb may be blocked and airspeed indications may actually be altitude related.

- Converting groundspeed to "indicated" airspeed. The old rule of thumb that says IAS is TAS divided by the sum of 1 and 2% of the altitude in thousands of feet. (Example to follow.) If you know this and have a rough idea of your headwind or tailwind, you will have a pretty good estimate.

- Known power and thrust settings. Even if none of your pitot-static systems is working, you should know a good thrust setting and pitch setting for at least three conditions: low altitude climb, high altitude cruise, and low altitude approach.

The TAS to IAS formula may seem complicated, but back in the days we had to do our flight planning manually, it was just one of those things you memorized. In case your mind works better with formulas:

For example, let's say you are at 20,000 feet and air traffic control or your GPS tells you your ground speed in 300 knots. You know that you have a 20 knot headwind, so your TAS is approximately 280 knots. Two percent (0.02) of 20 thousands of feet comes to 40 percent, or 0.40.) You add 1 to that to come up with 1.40. Your IAS, therefore, is equal to 280 / 1.40 = 200 knots indicated. I'll admit this may seem cumbersome and the only reason I have it memorized is that I had to rely on it for several years in the T-37 and T-38. But it might not be a bad thing to have in your hip pocket.

Regarding the absence of guidance and that last point about known power and thrust settings, I believe the Boeing 757 manual from 1990 – six years before this accident – included an unreliable airspeed indication procedure. That procedure included known thrust and pitch settings:

Unreliable Airspeed Indication Procedure (757/767, 1990s FCOM/QRH)

Condition: If airspeed or Mach indications are suspected to be unreliable, or if the “AIRSPEED DISAGREE” alert occurs.

• Memory/Immediate Actions (condensed):

1. Autopilot/Autothrottle — Disengage.

2. Flight directors — OFF.

3. Set pitch and power appropriate for the flight phase:

• Takeoff / Climb: 10° pitch, 80–85% N1 (two engines).

• Cruise (fl250–fl350): 2.5° pitch, 90% N1.

• Descent / Approach: 2–3° pitch, 60–65% N1.

4. Use standby instruments (standby ASI, pitch attitude, power settings) to continue safe flight.

• Follow-up: Cross-check against standby instruments and known power–pitch settings until reliable reference is restored.

Source: a ChatGPT representation of the 1990s Boeing 757/767 FCOM/QRH.

9

Final Note

Later that year another Boeing 757 crashed after the crew took off with the static ports covered with tape. That crew would have benefitted with the knowledge of what happened to Birgenair 301. In the case of Aeroperú 603, the crew was fooled into thinking their altimeter was correct because it agreed with the altitude seen by air traffic control, failing to realize the ATC altitude was based on that transmitted by the aircraft. They could also have benefitted by referencing their GPS groundspeed. Yes, groundspeed and airspeed are different. But it is another data point that may help to diagnose what is happening. More about the later crash: Case Study: AeroPerú 603.

References

(Source material)

Final Aviation Accident Report, Birgenair Flight ALW-301, Puerto Plata, Dominican Republic, February 6, 1996, Junta Investigadora de Accidentes Aéreos (JIAA) Director General of Civil Aeronautics, Dominican Republic.

Instrument Flying, Air Force Manual 51-37, Department of the Air Force, 1 December 1976

Lessons Learned, Birgenair Flight ALW 301, TC-GEN, February 6, 1996, U.S. Federal Aviation Administration, https://www.faa.gov/lessons_learned/transport_airplane/accidents/TC-GEN.