One of the problems with working for a discount airline is that you may find yourself flying a discount airplane with discount maintenance manuals, discount mechanics, and the person in the next seat could very well be a discount pilot. The problem is compounded when the maintainers are not given enough time for their tasks and are therefore encouraged to cut corners where they can. Pilots can find themselves as the last line of defense but that can be all for naught if the pilots are also in the short-cutting mindset. It seems the NTSB didn't put their best team on this one, the report is poorly written and doesn't teach the lessons that are needed. Perhaps they were in the short-cut mode too. Let's do better...

— James Albright

Updated:

2016-07-05

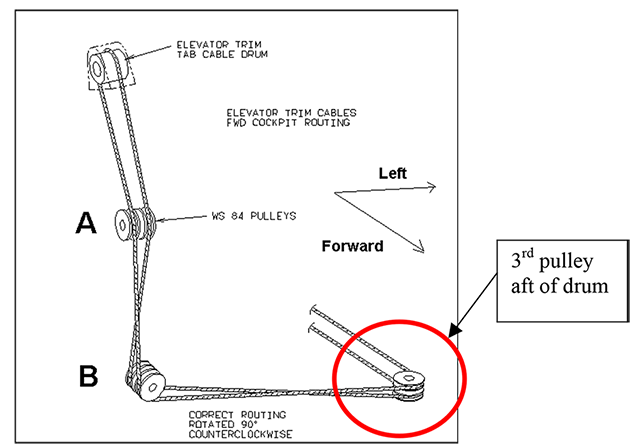

Colgan Air 9446 elevator trim cable,

from NTSB NYC03MA183, Figure 1.

- The airplane was in for a phase check where a binding elevator trim tab actuator was discovered. The actuators were replaced but then a kinked cable was discovered. The maintenance procedure required removal of the elevator, perhaps to gain free access to the cable pulley, but the mechanics skipped this step. The manual also required lead wires be used and identified to ensure the cables were correctly oriented. The mechanics didn't do this.

- Quality assurance inspectors verified the electric trim tab switches and manual trim wheel were working correctly. The manufacturer, however, did not provide a test procedure and it appears the inspectors didn't know what they were looking for. (The cables appear to have been routed backwards.)

- The pilots did not appear to treat this first flight after maintenance with the due diligence it deserved.

- The pilots did not accomplish a first flight of day checklist which would have required a trim system check.

- The pilots did not accomplish their checklists following engine start using a challenge and response and appear to have skipped the step requiring they set and check the elevator trim. It was set too far nose down for takeoff.

- After takeoff it appears the pilot tried to counter the nose down trim by electrically trimming nose up, but since the cable was routed backwards this resulted in further nosedown trim until it was fully nose down. The pilot misdiagnosed this as a case of runaway trim and was unable to recover.

The pilot's misdiagnosis of the problem was certainly understandable. It would have taken amazing situational awareness and presence of mind to try opposite trim; I doubt I could have done any better. But his actions up to that point were indicative of complacency. Maintenance caused this crash. The pilot could have (and should have) prevented it before they ever got off the ground.

1

Accident report

- Date: 26 August 2003

- Time: 15:40

- Type: Beechcraft 1900D

- Operator: Colgan Air

- Registration: N240CJ

- Fatalities: 2 of 2 crew, 0 of 0 passengers

- Aircraft Fate: Destroyed

- Phase: En route

- Airport (Departure): Hyannis-Barnstable Airport, MA (HYA/KHYA), United States of America

- Airport (Destination): Albany Airport, NY (ALB/KALB), United States of America

2

Narrative

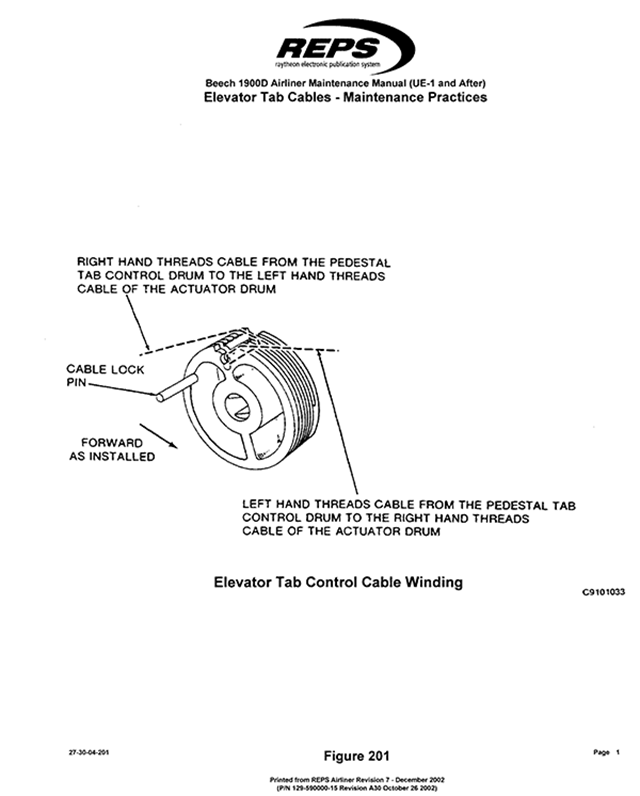

Colgan Air 9446 MM Extract, figure 201, NTSB NYC03MA183

- According to Colgan Air’s maintenance records, on August 23, 2003, aircraft N240CJ underwent a Detail Six (D6) phase check as part of its approved phase maintenance program using guidance from the Beech 1900D Airliner Maintenance Manual. The D6 check was performed at the Hyannis, Massachusetts (HYA) station beginning on August 23 at 1647.

- The Maintenance Program Manual (MPM) states that the emphasis of the D6 check is on the empennage and aft fuselage, which includes visual inspections, lubrications, free play checks, engine borescopes, engine mount torque checks, servicing, operational checks, and cable tension checks.

- The check was interrupted mid-stream (procedures for interrupting checks are contained in the General Maintenance Manual section 3.5.3) and the remaining work was deferred on August 24, 2003 at 0800. Ten revenue flight legs were conducted on Sunday August 24, and the D6 check was continued that night at 2030. The check was completed on Tuesday August 26, 2003 at 1100.

- According to Colgan Air’s maintenance records, on August 24, the maintenance technicians (MTS) performed workcard # 27-30-01 as part of the D6 work package. Section two of this workcard requires a free play check of the elevator trim tab actuators. The MTS accomplished the 19 steps for this check and found both left and right elevator trim tab (ETT) actuators to have failed the check. Failure of the actuators by this check requires replacement before further flight. Two actuators were ordered and four MTS were assigned - two to each actuator - to replace them.

- As per the BE1900D maintenance manual, replacement of the ETT Actuators requires accomplishment of all the manual procedures per the BE1900D maintenance manual (MM), 27-30-06. Interviews were conducted with: a maintenance technician, who replaced the left actuator the first day and the right actuator the second day; the lead technician (LT) on duty; and the Quality Assurance (QA) inspector who performed the required item inspection (RII). Per the interviews, the maintenance manual procedures were followed.

Source: NTSB NYC03MA183 Aircraft Maintenance and Records Group Factual Report, §5.0

The NTSB contradicts itself in the next paragraph. Were procedures followed or not?

- According to the interviews, the MTS chose to omit step (c) of the Elevator Trim Tab Actuator Removal and step (i) of the Elevator Trim Tab Actuator Installation.

Source: NTSB NYC03MA183 Aircraft Maintenance and Records Group Factual Report, §5.0

Step (c) in MM 27-30-06 simply says "Perform the ELEVATOR REMOVAL procedure" and sends you to the section of the manual that covers that, it is a big job. Step (i) says "Remove the mounting bolts and remove the actuator through the access opening." It appears these steps were skipped as a short cut, of course that would make routing cables much harder.

- Omission of these steps discounts nineteen maintenance steps required by the manufacturer’s MM in the process of accomplishing the ETT actuator replacements. These steps guide the maintenance technician through the removal and installation of the elevator control surface(s) and are the MM procedures 27-30-02.

- According to the interviews with the maintenance technician, the two ETT actuators were replaced and an operational check was conducted. In the process of performing operational checks, the ETT cable system seized. The maintenance technician took the pedestal panels loose to ascertain the problem with the cable system. The maintenance technician documented that the “Elevator trim tab cable fell off drum under pedestal” on Maintenance Work Order # 08477.

- The maintenance technician discovered that the ETT forward cable became kinked and ordered out a replacement cable. The necessary floorboards and access panels were opened to gain entry to the forward cable. The LT stated during an interview that management at Colgan Air had been in discussion with Raytheon Aircraft to determine if the part number of the right hand (R/H) ETT actuator was correct. It was found that the part number was incorrect and the R/H ETT actuator had to be replaced. This part was also ordered out under the correct part number.

- The ETT actuator and forward cable were delivered to the hangar the following afternoon, August 25, 2003. That night two MTS were assigned to replace the recently installed R/H ETT actuator and two MTS were assigned the ETT forward cable change. The forward cable was replaced per MM 27-30-04, while the R/H ETT actuator was replaced per MM 27-30-06. The steps (c) and (i), removal and installation of the right elevator, were omitted.

Source: NTSB NYC03MA183 Aircraft Maintenance and Records Group Factual Report, §5.0

These are the same steps called for earlier and once again a short cut was taken.

- As per interviews with the two MTS that performed the forward cable replacement, the drum assembly was removed in the cockpit during the dayshift, prior to their assignment to the forward cable change. The turnover from day shift to night shift did not contain written turnover notes of explicit work performed. Non-routine discrepancies on the Detail check were open that indicated that work was not complete.

- Per interviews, the two MTS did not use a lead wire when routing the cable through the forward cable pulley system. Attaching lead lines as part of the cable replacement is addressed in MM 27-30-04. Step (g) states, “attach lead lines to the aft ends of the forward cables and properly identify them to facilitate reinstallation.” One of the maintenance technicians marked the topmost cable pulleys with a letter “T” to facilitate re-assembly. Following the re-assembly both MTS checked the routing of the forward cable by referring to MM 27-30-04, figure 201.

Source: NTSB NYC03MA183 Aircraft Maintenance and Records Group Factual Report, §5.0

The MM requires lead lines and that these be properly identified. The MTS instead marked the pulley.

- The BE1900D maintenance manual does not contain an Elevator Trim System Operational check. The MTS stated that testing of the system was based on what they determined to be proper tests for properly testing the system components.

Source: NTSB NYC03MA183 Aircraft Maintenance and Records Group Factual Report, §5.0

Is the movement of an elevator trim tab intuitively obvious? I think even some pilots would have a difficult time rationalizing which way the tab should move to command nose up or nose down.

- According to interviews with the QA inspector and the LT, the ETT system was re-checked following the cable replacement performed. The system had been run full up and down travel several times, both electrically and manually. The QA inspector performed the Required Item Inspection (RII) function and was present at both the tail and the cockpit pedestal during all phases of the operational checks. The QA inspector was satisfied with the performance of the ETT cable system and the two ETT actuators and complied with the RII functions of the job.

Source: NTSB NYC03MA183 Aircraft Maintenance and Records Group Factual Report, §5.0

Did the MTS and QA inspector understand which way the elevator trim tab should have moved in response to the electronic trim tab actuator or the manual control? It appears they did not. Incredibly, the NTSB did not pursue this.

- During interviews, the two MTS working the forward ETT cable stated there was no confusion in the handling of the cable drum or how the manual illustration was interpreted. The MTS admitted to winding the cable and installing the drum to agree with the depiction in the manual. They further stated that the job went normally and that the operational checks were good.

Source: NTSB NYC03MA183 Aircraft Maintenance and Records Group Factual Report, §5.0

The report makes an issue of the depiction in the manual (figure 201 shown above) and perhaps rightfully so. But the MTS were not confused by it and I think it is a red herring. The problem was the short cut the MTS took in leaving the elevator installed and failing to use the lead wires to route the cables. That is why the elevator trim cable was routed backwards. The next issue was the manufacturer failing to delineate the operational check and the maintenance personnel assumption that they knew how the trim tabs should react to electrical or manual movement.

- According to a representative of Colgan Air Inc., after scheduled maintenance, the flightcrew was dispatched to fly the accident airplane on a positioning flight. The flightcrew was aware that maintenance was performed on the airplane; however, it was unknown if the flightcrew was aware of the type of maintenance.

- According to data from Federal Aviation Administration (FAA) air traffic control (ATC), the flight departed runway 24 at Hyannis about 1538. Shortly after takeoff, the flightcrew declared an emergency and reported a "runaway trim." The airplane initiated a left turn and reached an altitude of approximately 1,100 feet. The flightcrew subsequently requested to land on runway 33, and ATC cleared the flight to land on any runway. No further transmissions were received from the flightcrew.

- Witnesses observed the airplane in a left turn, with a nose-up attitude. The airplane then pitched nose-down, and impacted the water at an approximate 30-degree angle.

- According to data from the flight data recorder (FDR), the airplane began the flight at a pitch trim control position of approximately 2 degrees negative (nose down). Shortly after takeoff, the pitch trim control moved to approximately 3 degrees negative, where it remained for a period of about 10 seconds. The pitch trim control then moved to an approximate 7 degree negative position, where it remained for the duration of the flight. The data also revealed that after takeoff, the airspeed continued to increase to approximately 250 knots.

- The accident flight was the first flight after maintenance had been performed on the airplane; which included replacement of both elevator trim actuators and the forward elevator trim cable.

- Excerpts of the cockpit voice recorder (CVR) transcript revealed the following:

- At 1538:40, the first officer stated, "V1... rotate." About 6 seconds later, the captain stated, "we got a hot trim, Steve ... roll back Steve roll back roll back roll back roll back."

- At 1538:53, the captain stated, "I got it... (pull) back ... she's heavy buddy ... roll it back roll my trim Steve."

- At 1539:00, the captain stated, "do the electric trim disconnect... hold... all right, Steve ... hold back Steve"

- At 1539:04, the captain stated, "no go on the controls with me Steve." The first officer replied, "I got it."

- At 1539:14, the captain requested that the landing gear be raised, followed by the CVR recording sounds similar to landing gear motor noises.

- At 1539:18, the captain requested that the flaps be raised, which the first officer conformed that they were "up."

- At 1539:21, the captain radioed the HYA tower controller, requesting an emergency return to the airport, which the tower controller approved.

- At 1539:33, the first officer queried the captain, "you want the power back?" The captain replied, "pull the power back. pull the power back."

- At 1539:36, the first officer stated, "slowly," followed by the CVR recording sounds similar to a decrease in engine/propeller speed.

- At 1539:40, the captain stated, "all right, were gonna need both of us on this Steve."

- At 1539:48, the first officer stated, "(could) I pull the breaker?"

- At 1539:49, the CVR recorded a sound similar to an altitude alerter.

- At 1539:49, the captain stated, "pull the breaker Steve ... pull the breaker ... I got it if you've got the trim baby."

- At 1539:54, the first officer stated, "where is it?" The captain replied, "find it... look left of the silver thing, Steve. look left of the silver thing."

- At 1540:02, the first officer stated, "left of the silver thing?" The captain replied, "left of the silver thing Steve ... don't let go of the st- control Steve, just stay with me ... you pull back for all your worth, baby ... just keep (pulling/holding) back for all your worth .... Steve (pull/hold) back."

- At 1540:39, the CVR recorded, "terrain terrain. * pull up."

- At 1540:47, the CVR recorded, "woop woop pull up pull-"

- The recording ended at 1540:47

Source: NTSB NYC03MA183 Group Chairman's Factual Report, §D.

3

Analysis

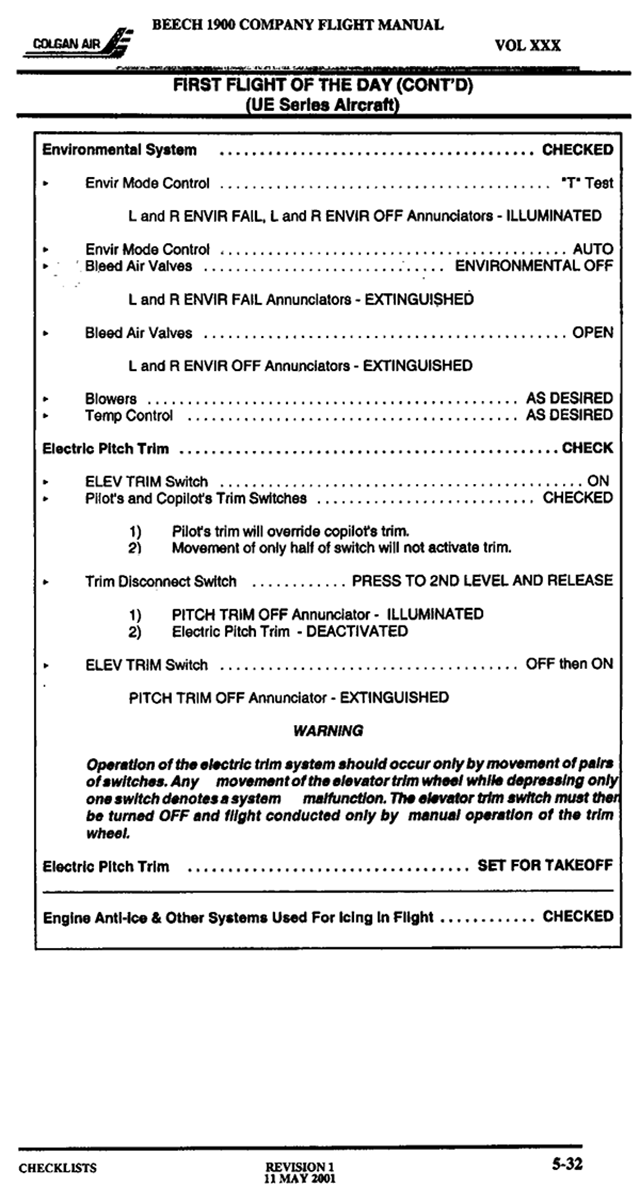

Colgan Air 9446 FOM Extract, from NTSB NYC03MA183

- The accident flight was the first flight after maintenance personnel replaced the forward elevator trim cable.

- When the flightcrew received the airplane, the captain did not address the recent cable change noted on his maintenance release.

Source: NTSB Statement of Probable Cause

An airline crew can easily get into the mode of accepting the next airplane, flying the next trip, and not thinking about anything out of the ordinary. The airline may have a designated functional check flight crew and line crews can simply assume everything is okay. But even a line crew needs to wary anytime the airplane comes out of maintenance. Especially when dealing with any flight control.

More about this: Functional Check Flights.

- The captain also did not perform a first flight of the day checklist, which included an elevator trim check.

Source: NTSB Statement of Probable Cause

It appears the elevator trim was also set incorrectly for the takeoff, leading one to believe even the shortened checklist was run haphazardly. Reading the transcript of the CVR we see the before starting engines checklist was done using a challenge and response but the after start was little more than the first officer saying "check check check check check check . . ." The word was repeated three times at one point, later seven times, then two times, and finally ten times. Hardly a challenge and response.

Pilots often argue the need for "Challenge-Do-Verify" (CDV) versus "Do-Verify" (DV) checklists. In my opinion there is no debate and a CDV would have saved this crew.

More about this: Checklist Philosophy.

- Shortly after takeoff, the flightcrew reported a runway trim, and manually selected nose-up trim. However, the elevator trim then traveled to the full nose-down position. The control column forces subsequently increased to 250 pounds, and the flightcrew was unable to maintain control of the airplane.

- During the replacement of the cable, the maintenance personnel skipped a step in the manufacturer's airliner maintenance manual (AMM). They did not use a lead wire to assist with cable orientation. In addition, the AMM incorrectly depicted the elevator trim drum, and the depiction of the orientation of the cable around the drum was ambiguous.

- The maintenance personnel stated that they had completed an operational check of the airplane after maintenance.

- The Safety Board performed a mis-rigging demonstration on an exemplar airplane, which reversed the elevator trim system. An operational check on that airplane revealed that when the electric trim motor was activated in one direction, the elevator trim tabs moved in the correct direction, but the trim wheel moved opposite of the corresponding correct direction. When the manual trim wheel was moved in one direction, the elevator trim tabs moved opposite of the corresponding correct direction.

Source: NTSB Statement of Probable Cause

The report here is either in error or there is more to what happened than meets the eye. According to the CVR, the pilot's initial reaction to the elevator trim set too nose down was to use the electric trim, as would be expected. His reaction would be to command nose up. But the report seems to say the electric trim was correct and the trim wheel was incorrect. I think they got this backwards.

4

Cause

The improper replacement of the forward elevator trim cable, and subsequent inadequate functional check of the maintenance performed, which resulted in a reversal of the elevator trim system and a loss of control in-flight. Factors were the flightcrew's failure to follow the checklist procedures, and the aircraft manufacturer's erroneous depiction of the elevator trim drum in the maintenance manual.

Source: NTSB Statement of Probable Cause

References

(Source material)

NTSB Aircraft Maintenance and Records Group Factual Report, NYC03MA183, March 16, 2004

NTSB Group Chairman's Factual Report, NYC03MA183, December 29, 2003

NTSB Statement of Probable Cause, NYC03MA183, 08/31/2004