So you are in a flight department without any Standard Operating Procedures (SOPs), you want some, but have no idea where to begin. Well let's try starting at the beginning! No, on second thought, let's start at the middle!

— James Albright

Updated:

2022-08-15

I've written a complete set of SOPs that was used by a management company I used to work for, has since been adopted by many other companies, and is currently in use at my company. These SOPs have been through countless audits, so they have been vetted. The only problem is that they are written for my operation, not yours. But you can easily adapt them.

There are eleven chapters and you might be best off by starting somewhere other than the first chapter, which is helpfully called Chapter Zero. But it would be a good idea to skim through everything: An SOP Starter Pack. Each chapter contains a presentation of the material, ideas on where to start, how to start, and a Microsoft Word Document file you can customize for you operation.

2 — SMS, ICAO, ISBAO and other alphabetty spaghetti

Note: If you already have a good set of SOPs and just need to incorporate a Safety Management System (SMS), or if you have an SMS program that seems to be little more than "window dressing" and want to make it really useful, take a look at the SMS Primer.

1

Why this chapter matters

This chapter sets out the flight department's Safety Management System (SMS). You may not think you need SMS, but you do. Yes, it is a requirement for international aviation. But even if you never leave the confines of your country's airspace, using SMS as it is intended will make your operation safer.

The SMS chapter includes:

- Your safety policy

- An operator risk profile

- Hazard Identification and Tracking System

- Continuous Improvement Opportunity System

- Audits, Evaluations, and Flight Operational Quality Assurance

- Fatigue Risk Management

It may be tempting to say "Safety First" and move on. In fact, that describes the safety program of many organizations. But you need to spell this out with statements that tell your people how safety is measured and that they have the freedom and your support to stop any unsafe practices.

You should take a moment to assess your operation from top to bottom and figure out if there is anything potentially unsafe. You should do this on a regular basis or whenever there have been changes to the organization. An operator risk profile shows you how to do this.

A formalized system to solve safety problems can help you come up with the best solutions and document your efforts to prevent lapsing back into the situation before the correction, as well as help build new solutions to new problems.

Having a formalized system to encourage new ideas gets everyone involved and can come up with brilliant solutions that might not have otherwise been devised.

You should have ways to track your progress to help identify where you fall short and where improvement is needed.

Being tired is a part of the job, right? Implementing a Fatigue Risk Management System is a good way of relieving the pressure from crewmembers and mechanics to press on when they are really too tired to be safe and effective.

2

SMS, ICAO, ISBAO and other alphabetty spaghetti

The International Civil Aviation Administration (ICAO) dictates how things happen in aviation worldwide, with exceptions permitted within a country's airspace. In the U.S., the Federal Aviation Administration has made quite a few exceptions, but has been working over the years to whittle those down in number. Even if you never venture outside the sovereign airspace of your country, ICAO rules will impact you at some point.

If you fly internationally, you will need a Safety Management System (SMS). Even if only fly domestically, you may find that an SMS is required by your operator or your insurance broker. You will definitely find that SMS will improve how you fly.

One of the ways you can demonstrate your adherence to SMS and other best practices is to get inspected by an approved auditor, such as the International Business Aviation Council (IBAC), who can measure you against the International Standard for Business Aircraft Operations (IS-BAO).

This chapter includes references to ICAO Annexes, which are the regulations that cover international aviation. Among the references throughout this chapter:

- "NX6" — Annex 6: Operation of Aircraft

- "NX19" — Annex 19: Safety Management Systems

3

The chapter itself

Note: I have used "Acme Corp" as the company name. Unless that is your company's name, you should substitute your company's name wherever you see Acme Corp.

2 Safety Management System

[NX6 3.3.2, NX19 4.1.1, NX19 4.2.1, NX19 A.1.5.2, and NX19 A.1.5.3]

The Acme Corp Flight Department operates with safety as our first priority. Acme Corp uses a Safety Management System to ensure that the Flight Department consistently provides safe air transportation by identifying safety hazards, analyzing the hazards, and eliminating or avoiding the hazards. Where hazards cannot be eliminated or avoided, mitigation is developed, implemented, and tracked to reduce the hazards and the associated risk to an acceptable level. Acme Corp Flight Department values people dedicated to a safe work environment. With this in mind, all flight department personnel are active participants of the safety team. We are all responsible for maintaining the highest standards of safety at all times.

2.1 Safety Policy

[NX19 A.1.1, NX19 A.1.2, NX19 A.1.5.1, NX19 A.1.5.2 and NX19 A.3.3]

Acme Corp Flight Department is committed to developing, implementing, and improving appropriate strategies, management systems, and processes to ensure that our aviation activities uphold the highest level of safety performance and meet national and international standards.

Our commitment is to:

a. Develop and practice a safety culture across our entire aviation operation that recognizes the importance and value of effective aviation safety management and acknowledges that safety is paramount

b. Clearly define staff accountabilities and responsibilities for the development and implementation of safe practices and procedures

c. Provide the staff with adequate and appropriate aviation safety information and training to enable them to implement safety strategy and policy

d. Comply with, and wherever and whenever possible, exceed legislative, regulatory, and corporate requirements and standards

e. Ensure externally supplied systems and services that affect the safety of aviation operations meet appropriate regulatory and safety standards

f. Establish and measure aviation safety performance against objectives

g. Foster a learning environment by which we learn from our experiences and the experiences of others

h. Regularly conduct safety and management reviews leading to improved processes

i. Actively develop and improve the safety performance to conform to world class safety standards

j. The Director of Safety will report directly to the Director of Aviation and be responsible for managing the aviation safety program

Each individual will always act with safety in mind because we have a responsibility to work in a safe manner. The application of effective aviation SMSs and processes is integral to aviation activities. The objective is to achieve the highest standard of aviation safety and performance.

Personnel should actively report safety issues without fear of reprisal.

Safety Policy will be reviewed annually by the Director of Aviation to ensure it remains relevant to the Company and that it reflects management commitment to maintain and improve the overall effectiveness of the SMS. All necessary documents and information will be made available to employees to help maintain a safe operation.

2.1.1 Purpose

The purpose of the safety policy is to manage safety pro-actively and effectively. This is done by:

a. Obtaining consistent and optimal aircraft and human performance

b. Identifying and managing safety risks specific to the company’s flight operations

c. Actively seeking feedback on and improving safety management activities

2.1.2 Responsibilities

[NX19 A.1.1, NX19 A.1.2, NX19 A.1.3, NX19 A.1.5.2]

a. The Acme Corp CEO is responsible for:

i. Sustaining conditions that advance the safe operation of company aircraft

ii. Providing the resources (in time and money) to assure the safe operation of company aircraft

iii. Actively supporting the safety management system

b. The Director of Aviation is responsible for:

i. Ensuring that flight operations are conducted in compliance with all applicable safety regulations

ii. Administering the safety management system

iii. Validating and addressing safety risk management deficiencies in an appropriate and timely manner

iv. Periodically reviewing the company safety policy to ensure it remains relevant to Acme Corp Flight Department

c. Flight Department personnel are responsible for:

i. Adhering to directions contained in flight operations related manuals, and related procedures

ii. Participating pro-actively in the safety management system by:

A. Actively identifying, reporting and mitigating hazards and safety risk management deficiencies

B. Providing timely input to management to ensure that the company’s safety risk profile is accurate and up to date

C. When appropriate, applying hazard checklists to identify and correct work hazards.

NOTE: Acme Corp will not initiate disciplinary measures against any employees for reporting safety issues. However, employees will be held accountable for knowingly disregarding established policies and procedures or otherwise engage in willful misconduct.

2.1.3 Related Documents

[NX19 A.1.5.2]

Acme Corp Flight Department shall establish and maintain information, in paper or electronic form, to describe:

a. Safety policies

b. Safety objectives

c. SMS requirements

d. Safety related procedures and processes

e. Responsibilities and authorities for safety related procedures and processes

f. Interaction/interfaces between safety related procedures and processes

g. SMS outputs

Documentation and/or records, either in paper or electronic form, shall be legible, dated (with dates of revisions), readily identifiable, maintained in an orderly manner, and retained for a specified period of time as determined by Acme Corp Flight Department.

2.2 Employee Safety Training

[NX19 A.4.1.1 and NX19 A.4.1.2] [Appendix C]

The Director of Safety will be the primary point of contact on all Safety Management System issues and should subscribe to all available National Business Aircraft Association (NBAA) and International Civil Aviation Organization (ICAO) online training resources. As time permits, Acme Corp will consider sending the Director of Safety to appropriate SMS courses as they become available. The Director of Safety, in turn, will train members of the flight department for their SMS duties and responsibilities.

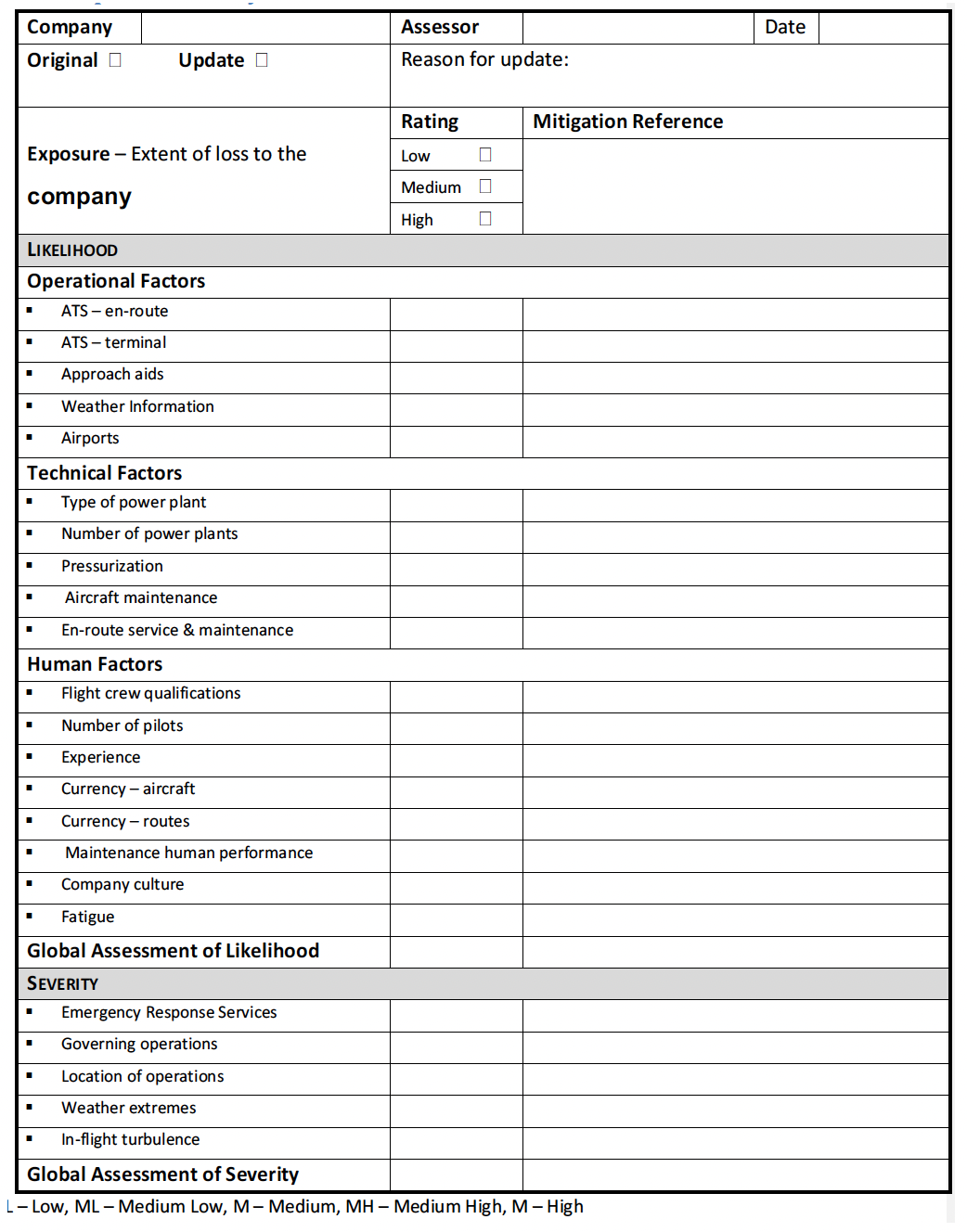

2.3 The Operator Safety Risk Profile

The 2.3.3 Operator Safety Risk Profile is a tool that identifies areas of higher risk. It is the basis on which the company safety management system is developed, implemented and evaluated.

Operator Safety Risk Profile factors are rated as:

a. Low – L

b. Medium low – ML

c. Medium – M

d. Medium high – MH

e. High – H

When the risk profile is completed it will be filed in the Company Safety Management filing system.

The risk profile will be reviewed at least annually, and any time the company undertakes significant change in its operations, or the aircraft it operates.

2.3.1 Mitigations

References will be provided on the form for mitigations that are contained in the Company Operations Medium or Higher Risks.

While all areas of risk are considered, those assessed as “medium” or “higher” in the Acme Corp Safety Risk Profile will receive special attention in the development of the Technical Management System and in managing the day today operations of the Flight Department.

2.3.2 Previously Identified Risks and Mitigations

The following is a listing of the areas of risk assessed as medium or higher and a description of the tools, processes and procedures developed to mitigate them and the associated company safety performance goals. Also included are the evaluation mechanisms that Acme Corp will use to evaluate the results of these initiatives.

2.3.2.1 Hazards/Mitigations

a. Fatigue Mitigation: Crewmembers will follow Extended Duty Day procedures, 3.4 Flight and Duty Period Limitations will not be questioned if the trip is modified to acquire proper rest

b. Special Operations Airports: Crewmembers will review Special Operations Airports and perform the 4.5 Special Operations Airport Checklist

c. MEL Considerations: Review MEL for Remarks/Exceptions and operational procedure considerations. Contact the Director of Maintenance if any questions arise regarding previous MEL items or when adding MEL items

d. Adverse Weather Operations: Review FlightRisk Analysis, Review Section 4.3.3 Operating Weather Minima and/or Section 5.2.9 Aircraft Critical Surface Contamination

e. New Aircraft Type: Adhere to Crew Qualifications/Pilot Operating Experience, 7.1 Flight Crew Currency for new type ratings. Attend recurrent simulator training every 6 months.

2.3.3 Operator Safety Risk Profile

2.4 Safety Management Strategy

The core Acme Corp operating philosophy stresses the importance of achieving the following priorities in the following order:

Safety Passenger Requirements

Schedule

Every decision, from aircraft maintenance to real time cockpit decisions, can be weighed against these priorities. Safety, as the highest priority, must be continuously evaluated in a proactive manner. Every member of the flight department serves as a safety officer and has direct access to the Director of Safety, the Director of Aviation, and the CEO of Acme Corp on all safety related matters.

2.4.1 Safety Performance Indicators

[NX19 A.3.1.1, and NX19 A.3.1.2]

2.4.1.1 Goals

The safety objective is to ensure zero level of preventable injury or damage situations.

a. Safety will be recognized by management and employees as an integral and vital part of the successful performance of any job

b. Safety, being paramount to our operating practice, will be given priority at all times

c. Direct responsibility for the safety of an operation rests with the supervisor of each operation. During flights the designated Pilot in Command (PIC) is the supervisor of each operation and will seek to ensure that all operations are conducted without incident

d. Each individual employee will perform their duties giving primary concern for their own safety as well as that of their fellow employees, our customers and the property and equipment entrusted to their care

e. The PIC is the judge as to whether the aircraft shall takeoff and where it shall land, considering all factors of equipment and weather conditions within the specifications of the Operations Manual and/or the specific Airplane Flight Manual. He/she will exercise this responsibility effectively and will use all the resources available to make appropriate and effective decisions

f. The PIC has ultimate authority to refuse or discontinue a trip which, for reasons of safety or security, he/she feels should not be attempted or continued. He/she will exercise this responsibility effectively and will use all the resources available to make appropriate and effective decisions

2.4.1.2 Strategies

To achieve this, the Acme Corp SMS must be proactive, ongoing and fully integrated throughout the Flight Department and all its activities. Accordingly, the following strategies are important:

a. All Flight Department employees and users will be involved in the flight department safety management system

b. Employee awareness, compliance, inspection, investigation and education programs will be incorporated into all aspects of the operation

c. All employees will endeavor to identify, report and eliminate non- normal and hazardous conditions

d. Specific Safety Performance Targets will be set for three areas of operations. Safety Performance Indicators will track the targets on a quarterly basis to help eliminate or mitigate non-normal and hazardous conditions

e. All reported hazardous events will be investigated to determine root cause

f. All proposed new equipment acquisitions, facilities, operations and procedures will be reviewed with safety in mind

g. All employees will ensure that all applicable laws and regulations are complied with

h. All employees will be trained to handle and/or operate any new equipment applicable to duty position acquired for the flight department

2.5 Hazard Identification and Tracking System

[NX19 A.1.1, NX19 4.2.2, NX19 A.2.1.1, NX19 A.2.1.2 and NX19 A.2.2]

2.5.1 Hazard Identification Program

[NX19 A.3.3]

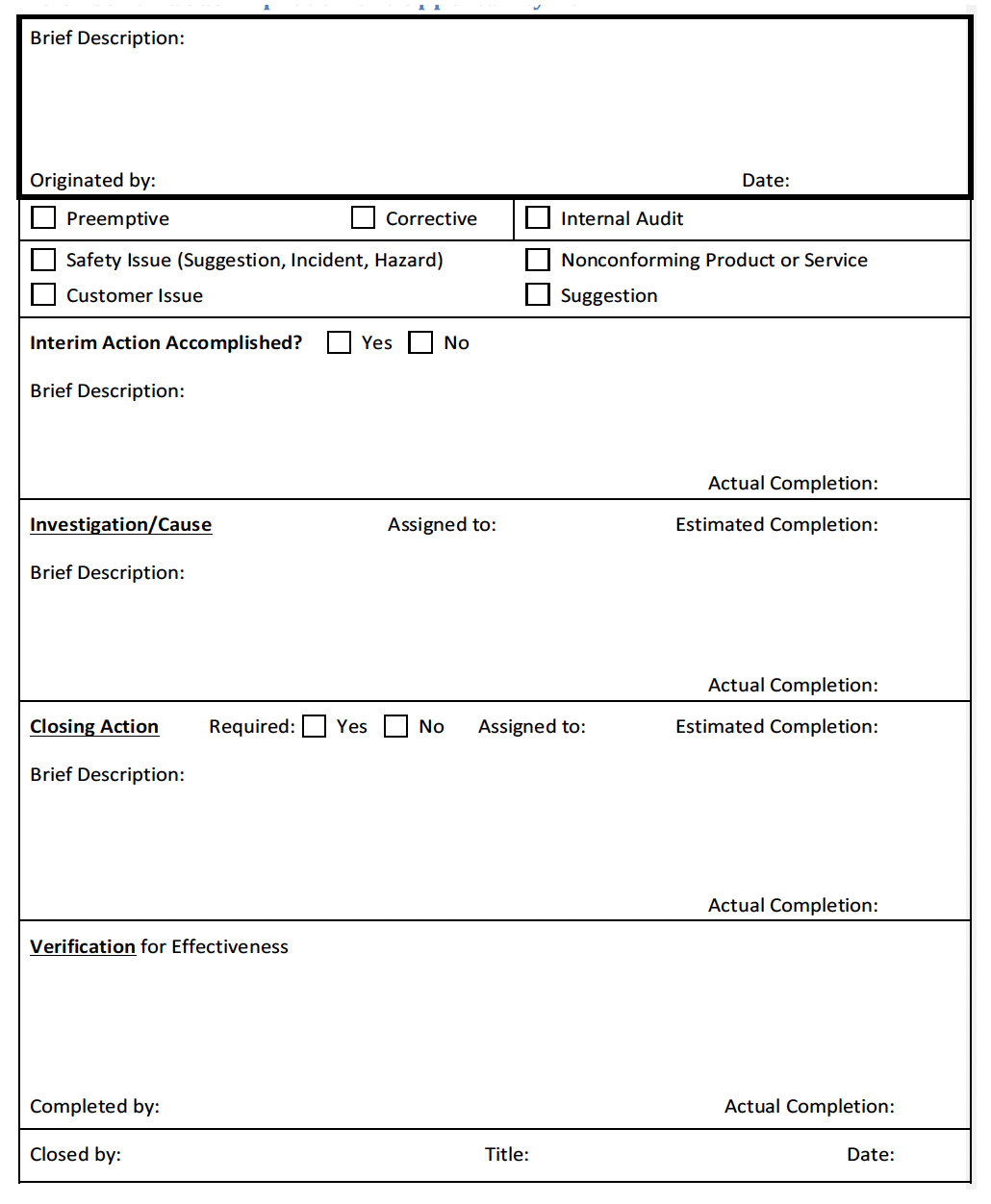

The purpose of a hazard identification program is to pro-actively identify and address potential deficiencies in safety management. All Flight Department employees and persons carried on Acme Corp aircraft are expected to participate in the hazard identification program. Reports/ observations can be made to the Director of Aviation verbally, but written reports are encouraged. Where verbal reports are provided, the manager shall prepare a report containing the information. Written reports can be made using the 2.5.3 Hazard Identification and Tracking Form.

Suggestions for improvements in areas which fall below the “hazard threshold” can be made using the 2.6.3 Continuous Improvement Opportunity Form.

2.5.2 Hazard Tracking System

The flight department Directors of Safety and Standards will analyze all hazard reports and a response will be provided to the person making the report. If it is determined that a modification to a procedure process or program is required, such information will be entered on the 2.5.3 Hazard Identification and Tracking Form and tracked until the remedial action has been completed. Written reports will be filed in the Company Safety Management filing system and reviewed on an annual basis to determine the effectiveness of the remedial measures.

Hazard identification and tracking will be an agenda item at each of the Flight Department quarterly staff meetings.

2.5.3 Hazard Identification and Tracking Form

2.6 Continuous Improvement Opportunity System

2.6.1 Continuous Improvement Opportunity Program

The purpose of the continuous improvement opportunity program is to pro-actively identify and address potential deficiencies in daily operations and that, in some cases, if left unattended may become hazardous. All Flight Department employees and persons carried on Acme Corp aircraft are expected to participate in the Continuous Improvement Opportunity Program (CIOP). Reports/observations can be made to the Director of Aviation verbally, but written reports are encouraged. Where verbal reports are provided, the manager shall prepare a report containing the information. Written reports can be made using 2.6.3 Continuous Improvement Opportunity Form in this section.

2.6.2 Continuous Improvement Opportunity Program Tracking

The flight department Directors of Safety and Standards will analyze all written reports and a response will be provided to the person making the report. If it is determined that a modification to a procedure, process, or program is required, the Director of Safety will confer with the Director of Aviation. Upon implementation of a modification, the action will be tracked for Verification for Effectiveness and noted on the written report. Written reports will be filed in the Company Safety Management filing system and reviewed on an annual basis to determine effectiveness of the remedial measures.

CIOP will be an agenda item at each of the Flight Department quarterly staff meetings.

2.6.3 Continuous Improvement Opportunity Form

2.7 Safety Risk Management

[NX19 A.2.2]

Acme Corp will use the FlightRisk Analysis tool for flight risk assessments. This tool will complete a preflight risk assessment by analyzing thousands of data points – pilot, environmental, airfield, and aircraft – relating to a proposed flight.

Acme Corp pilots and flight coordinators also have the ability to complete preflight risk assessments using the FlightRisk Analysis application. FlightRisk Analysis reports are archived with other trip documents for later recall and analysis. The number of Hazards, Information entries, and Warnings are recorded on the Post Flight Form to indicate the crew have reviewed the information.

2.7.1 Other than Routine FlightRisk Assessment

For other than routine flights, a preliminary FlightRisk Analysis will be completed by the PIC or the Flight Coordinator.

Situations that define other than routine flight:

a. Extended duty day/Operations within the WOCL

b. Severe warm weather operations

c. Severe cold weather operations

d. No takeoff minima specified or takeoff minima below standard

e. International trips other than Canada

f. Airports with no published standard takeoff minimums

g. Special operations airports (use in conjunction with 4.5 Special Operations Airport Checklist)

h. Aircraft items on CASS/MEL

i. Pop up trips

2.7.2 Overall Risk and Safety Performance

For overall risk and safety performance Safety Performance Targets (SPTs) will ideally be zero negative indicators. Since this is an ideal, Safety Performance Indicators (SPIs) will be used to track negative indicators.

Negative indicators will be reviewed quarterly. Mitigations will be applied to reduce negative indicators to the lowest number of events possible. Three operational areas will be tracked.

a. Flight operations will be tracked using Gulfstream FORMS program (eFOQA)

b. Maintenance operations will be tracked using Maintenance Evaluation Checklist.

c. Fatigue will be tracked using 3.4.3 Duty Day Exception Form

2.8 Technical Management System

The technical management system includes the COM, standard operating procedures for each aircraft, maintenance programs as described in Chapter 8 Aircraft Maintenance, and subscriptions to:

a. The United States civil aviation regulations

b. Flight planning information documents and flight publications that will be used by flight crews

c. Minimum Equipment List

d. Configuration Deviation List

The Chief Pilot will maintain a complete list of required publications needed for flight operations and ensure the list reflects what is actually available for flight crews and other personnel. The Director of Standards will check the list quarterly to ensure all required publications are up to date. When items are changed the revision list will be updated.

2.9 Preventive/Corrective Actions

[NX19 A.1.1]

a. Corrective actions are the end result of a successful investigation or audit. The report should indicate whether these actions are recommended, planned, or completed. Actions should be specific, feasible, and consist of one of three types:

i. Actions to eliminate the cause or causes of the accident or incident

ii. Actions to control the circumstances that caused the accident or incident

iii. Personnel actions such as improved procedures, increased or enhanced training, or discipline of employees involved in the occurrence.

b. Proposed corrective actions will be reviewed by the leadership team and safety staff.

i. Corrective actions should be carried out by appropriate managers. The final report should be communicated to employees

ii. Periodically monitor the success and continuation of the corrective action to ensure that the erroneous behavior does not recur

2.10 Safety Management System Audit

2.10.1 Independent Audit

A Safety Management System audit is an independent evaluation of the safety management system of a company. While such an audit may be done to meet an external requirement, the prime purpose of a Safety Management System Audit is to identify areas in which safety performance may be evaluated and enhanced. A Safety Management System Audit is used to validate the corporate safety risk profile, which in turn shall be employed as the basis to evaluate corporate safety performance. It may include:

a. Visits to one or more operating sites

b. Interviews with managers and operational staff within and outside of the company

c. Document reviews (e.g. for completeness, currency and appropriateness)

d. An evaluation of the safety management tools being employed by the company

Findings from a Safety Management System Audit will be tracked in the hazard tracking system and may be used to update 2.3.3 Operator Safety Risk Profile and the Safety Management Strategy.

2.10.2 Internal Audits

Acme Corp will conduct internal audits on a triennial basis. The audit will involve all flight department personnel to ensure conformity and satisfaction with the handling of all submitted HIT and CIO forms. All flight department personnel will participate in the completion of an Assessment Tool to further determine the effectiveness of flight department procedures.

2.10.3 Compliance Monitoring

Ensuring the Acme Corp Safety Management System remains in compliance with all applicable regulations, standards, approvals, and exemptions is a shared responsibility among all members of the flight department. Ops Group notices will be reviewed daily. ICAO/BASC IEP protocols are issued annually and will be reviewed on an annual basis. In the interest of applying the proper focus to task the division of duties has been assigned as follows:

a. Director of Aviation/Chief Pilot: International flight operations, to include ICAO and JAA, our International Operations Manual and this Company Operations Manual

b. Director of Standards: Safety Management System, U.S. Code of Regulations, and the International Standards for Business Aircraft Operations

c. Director of Safety: Safety Management System, Safety related publications and the National Business Aircraft Association

2.10.4 SMS Evaluation

At the conclusion of an external SMS audit the Director of Aviation will complete an evaluation of the appropriateness and effectiveness of the SMS. The evaluation will be based on the safety performance goals and strategies identified in Section 2.9 Preventive/Corrective Actions. An SMS evaluation will be developed and implemented for any shortcomings identified in the evaluation. When the evaluation is completed, it will be passed to the Accountable Executive for approval.

The results of the evaluation and any corrective action plans will be tracked through the Hazard Identification and Tracking System.

2.11 Change Management Process

[NX19 A.3.2]

When a report is received through the Hazard Identification and Tracking System or information gained through any other process results in the decision to modify a process, procedure or program the proposed change will be reviewed by the Director of Aviation.

2.11.1 Implementation

a. Approved changes will be implemented in accordance with the following procedures:

i. The change process including the risk assessment, will be recorded

ii. The amended process or procedure or information in the amended program, will be distributed to all flight department personnel at the quarterly Safety Meeting by the Director of Aviation or person assigned the task

iii. The operations manual and other associated documentation will be amended and distributed to all document holders

b. If the change is disapproved, the reasons will be provided to the submitter.

i. If the submitter agrees with the rationale, the matter is considered closed

ii. If the submitter does not agree with the rationale, the change request will be amended to consider the rationale and reconsidered by the process

2.11.1.1 Possible Change Management Causes

Prior to undergoing any significant change that could impact the Flight Department; a change management process will be undertaken. Events that will indicate the need for such a process are:

a. The introduction of a new aircraft type

b. Significant change in the nature of the operation (e.g. dynamic business growth, new operating environment, etc.)

c. Changes in hiring or scheduling practices

d. Changes to organizational structure

e. Significant change in aircraft maintenance arrangements, etc.

2.11.2 Review

As soon as it has been determined that the change event will occur, the Company Safety Risk Profile will be reviewed. Based on that assessment, and any other available information, the Director of Aviation, or the person to whom the responsibility is delegated, will develop a Change Management Plan. The Change Management Plan will include:

a. A risk analysis of the change event and an assessment of the changes required to items such as:

i. Operating and maintenance procedures and processes

ii. Personnel training and competency certification

iii. Company Operations Manual

iv. Maintenance Control Manual or Maintenance Procedures Manual

v. Aircraft SOPs, etc.

b. A plan for development of the required changes

2.12 Flight Operational Quality Assurance

2.12.1 Purpose

The driving force behind the implementation of the Acme Corp FOQA program is the improvement of safety. The FOQA program is used to reveal operational situations in which risk is increased in order to enable early corrective action before that risk results in an incident or accident.

2.12.2 FOQA Program Officer

The Director of Safety is responsible for the FOQA program.

2.12.3 Integration

The FOQA is interfaced and coordinated with the total safety program. The FOQA program is a part of the operators overall operational risk assessment and prevention program as described in 2.7 Safety Risk Management.

2.12.4 Data Collection

2.12.4.1 Automatic data Collection

Aircraft information is captured by Gulfstream Aerospace FORMS.

2.12.4.2 Voluntary Data Collection

The 2.3.3 Operator Safety Risk Profile, the FlightRisk Analysis, the 2.5.3 Hazard Identification and Tracking Form, the 2.6.3 Continuous Improvement Opportunity Form, and Safety/Service Issue forms (ARINC FOS) are provided as a means to allow all members of the Acme Corp team to provide voluntary data for the FOQA.

2.12.5 Data Analysis

Because the true value of a FOQA system is realized in collecting large samples of data, the Director of Safety will meet quarterly with the Director of Aviation, the Director of Maintenance and the Director of Standards to correlate the Acme Corp data with other corporate aircraft. The aggregate data is then analyzed to evaluate or effect change in any or all the following areas:

a. Operational Safety

b. Aircraft Performance

c. Aircraft System Performance

d. Crew Performance

e. Company Procedures

f. Training Programs

g. Training Effectiveness

h. Aircraft Design

i. ATC System Operation

j. Airport Operational Issues

k. Meteorological Issues

2.12.6 Analysis Techniques

Two types of analysis techniques are applied to FOQA data.

2.12.6.1 Exceedance Analysis

Data will be analyzed against known standards.

2.12.6.2 Statistical Analysis

When large databases are available, statistical tests will be applied to determine trends against known standards.

2.13 Fatigue Risk Management Program

The Acme Corp Fatigue Risk Management Program (FRMP) is a part of the overall safety management system. The objective of the FRMP is to outline policies and procedures to all operator personnel involved in the safe operation and maintenance of the aircraft so that they do not carry out their duties when fatigued and to reduce the risks of fatigue. The Director of Safety will collect data on fatigue to further improve the management of fatigue.

2.13.1 Fatigue Risk Management Policies

2.13.1.1 Individual Responsibility

Individuals are expected to report fit for duty. Employees are expected to report for duty sufficiently well rested to be able to safely perform the duties of the job. Likewise, it is the responsibility of the individual to alert the Director of Aviation when not sufficiently rested to perform safely. The Director of Aviation, in turn, must either replace that person with someone who is well rested or take measures to reschedule or adjust the schedule as required.

Individuals who are too fatigued to drive home should stay at a local hotel or have a car service drive them home.

2.13.1.2 Absent for Fatigue

“Absent for fatigue” policy. Individual reporting absent because of fatigue will not be coerced into performing duties anyway. Repeated instances will be treated on a case by case basis, outside of normal trip times.

2.13.1.3 Trip Scheduling, Flight Crew

Acme Corp scheduling policies assure that the organization adheres to all applicable Federal Aviation Administration flight and duty time regulations, with the additional restraints contained in 3.4 Flight and Duty Period Limitations. Flight crews will discuss fatigue concerns, rest requirements and 3.4.2.1 WOCL Flight and Duty Limitations operations if applicable.

2.13.1.4 Standby Periods, Flight Crew

Standby periods for flight crew are from 0800 to 1700 local. Aircraft should be able to be airborne in five hours from initial call. During “Hot Standby” the aircraft should be able to be airborne in three hours form initial call. “Hot Standby” will be no more than two consecutive days in a row.

2.13.1.5 Scheduling, Ground Crew

Whenever possible, ground crew personnel should plan work days during normal 0800 – 1700 hours following adequate rest. When the work load demands starting a duty day outside normal 0800 – 1700 hours, ground crew personnel should evaluate their personal fatigue levels and curtail duty periods as needed. Regardless, ground crew personnel should be aware of his/her personal fatigue limits and understand that sometimes the standard eight hour day cannot be used as the sole determinant of when it is safe or not to continue duties. The company will fully support anyone’s decision to stop work because of personal fatigue in the interest of safety.

In the case of maintenance crew, if the aircraft is not in a ready condition for subsequent flights the Director of Maintenance will determine a ready time based on the next duty period available and advise the Director of Aviation. If the aircraft will be needed prior to that period, the Director of Maintenance will contract the necessary personnel to meet scheduling requirements, if possible.

In no case will any ground crew personnel work more than 16 continuous hours in any 24 hour period.

2.13.1.6 Reporting

Individuals may report errors and events related to fatigue to the Director of Safety, who will evaluate the incident and determine follow up actions.

Forms for reporting are contained within 2.5 Hazard Identification and Tracking System and 2.6 Continuous Improvement Opportunity System. Reports of adverse events that may be attributable wholly or in part to fatigue can serve as a mechanism for obtaining all relevant information regarding fatigue contributions to the incident.

2.13.1.7 Post Trip Review

The Chief Pilot will evaluate the results of every trip to ensure Acme Corp duty limitations, as outlined in 3.4 Flight and Duty Period Limitations, are adhered to, and will investigate instances which indicate high levels of fatigue risk.

2.13.1.8 Fatigue Risk Management Working Group

The Director of Safety will address fatigue risk management topics at the quarterly safety meeting as required. Following this meeting the Directors of Safety and the Director of Standards will review the previous quarter’s trips, HIT and CIO reports from individuals, 3.4.3 Duty Day Exception Form and the expected schedule. The Director of Safety will report any findings and recommendations to the Director of Aviation.

2.13.1.9 Education and Training

Fatigue is a complex topic and all crewmembers should have adequate training to understand the causes of fatigue, how an individual can maximize the benefits of rest opportunities, the use of various countermeasures to minimize the effects of fatigue, and the overall responsibilities of the individual to report for duty fit to safely perform duties. The Director of Safety will ensure all flight department members receive the training detailed in 7.17 Fatigue Management Training.

2.13.2 Fatigue Risk Management/Mental and Physical Well Being

2.13.2.1 General

Personnel will be mentally and physically alert and free from any effect produced by insufficient rest, alcoholic beverages, or medically unauthorized or illegally used drugs.

2.13.2.2 Rest/Managing Fatigue

Crewmembers are expected to use good judgment concerning adequate rest prior to duty and reporting fit for duty when under serious mental stress (i.e., serious personal problems, serious family illness, etc.). When the latter conditions exist, crewmembers are encouraged to discuss the situation with the Chief Pilot. Crewmembers should recognize the following symptoms as the onset of a potentially dangerous situation.

a. Symptoms

i. Eyes going in and out of focus

ii. Head bobbing involuntarily

iii. Persistent yawning

iv. Wandering or poorly organized thoughts

v. Spotty near term memory

vi. Missed or erroneous performance of routine procedures

vii. Degradation of control accuracy

NOTE: There are recognized counter measures for fatigue that have been shown to be effective in improving alertness and performance. These include long naps of three to four hours, which can significantly restore alertness for 12 to 15 hours.

Short or “Power Naps” of 10 to 30 minutes can help restore alertness for 3 to 4 hours. However, no “naps” will be allowed on the flight deck by crewmembers. A pilot should allow 15 to 20 minutes after awakening to become fully alert before assuming aircrew duties.

b. Other countermeasures include:

i. Eat high protein meals (avoid high fat high carbohydrate foods)

ii. Drink plenty of fluids especially water

iii. Caffeine can help counteract noticeable fatigue symptoms if awake for 18 hours or less

iv. Rotate tasks and converse with other crewmembers (use good CRM procedures)

v. Keep the flight deck temperature cool

vi. Move or stretch in the seat and periodically walk around the aircraft if possible

vii. Gradually shift times for sleep, meals, and exercise to adjust to new time zones

2.13.3 Minimum Quarterly Duty Free Days

2.13.3.1 Policy

All pilots will be given at least 13 duty free days per quarter of which at least 5 must be scheduled in advance. The 5 day requirement is scheduled at least a month in advance, “looking forward” The 13 day requirement is evaluated after the quarter, “looking back” Vacation days, if requested, have priority and are counted as satisfying the 13 day requirement. If no vacation is used during the quarter, the 13 day requirement must still be met.

2.13.3.2 Looking Forward

The 5 day requirement will not count as vacation time and must be requested at least a month in advance. The days need not be consecutive. Once these days are scheduled, they will only be changed with the pilot’s agreement. The Director of Aviation will normally grant the requested days unless an operational need has to be met, other pilots have training requirements or other pilots have scheduled vacation time. If a pilot has not selected 5 days off prior to the second month of a quarter, the Director of Aviation will assign the days off. The intent of these duty free days is to provide a break from duty requirements. Therefore, the 5 day duty free period cannot be scheduled immediately before or after a vacation period. There must be at least 5 days available for duty before and after.

2.13.3.3 Looking Backward

The Director of Aviation and Flight Coordinator will monitor pilot workloads during each quarter to ensure every pilot will finish each quarter with at least 13 days free of duty. These days may include weekends, holidays, vacation days, and the 5 day looking forward duty free days. If the requirement was not met, the Director of Aviation must ensure the balance of the 13 day requirement is met in the month following the completed quarter.

4

Where to start

Getting started with SMS can be intimidating until you break it down to its component parts. You first need a safety policy which basically says: be safe. Then you need a way to allow people to let everyone know when things aren't safe. And then a way to fix that. There . . . you now have a Safety Management System.

You might feel some (or all) of this is making much ado about nothing. I used to think that. But after just a few months with the system we had someone point out our wing walkers were not paying attention to the wings they were walking. My fix would have been simple: keep an eye on the wingtips! The group fix was far more effective: empowering anyone on the team or observing the team to stop the entire operation if they spotted anyone using a cellphone, having an idle conversation, or in someway not paying attention. Since the group came up with the solution, everyone had a vested interest in following their procedure.

5

How to start

With each chapter it is a good idea to:

- Talk it over with your team, get their ideas on how to best accomplish the chapter's goals given your unique situation. All ideas are worth considering, write them down in a way the person offering it agrees fully captures the idea.

- Give the team time to digest the proposals.

- Ask the people with the right background to massage the ideas into concise concepts, then have your best wordsmith turn those concepts into paragraphs. The paragraphs need to be in plain spoken sentences, easy to read, and written at the fifth grade level of comprehension.

- Present the ideas to the group. Listen to any objections and seek consensus. Repeat the entire process if needed, but understand that the person in charge will eventually make a decision that becomes department policy. At the very least, stress that each policy can be tested on a trial basis and looked at again in the future.

6

Word file

You can download a Microsoft Word "docx" file of this chapter here: Acme Corp Operations Manual Chapter 2 - Safety Management System.

Remember, this is your blank canvas to customize as you see fit.