Fly by Wired is primarily a story of people shaped by their experiences growing up trying to find their places in the world, only to find themselves caught up in a plot to "tear down the whole system." One of the characters attempts to use the computerized flight control systems on some business jets to this end. The "Fly By Wire" system removes all mechanical controls between the pilots and their flight controls, replacing them with digital signals along wires. These fly-by-wire systems were at first controversial, few were willing to give up that kind of control to computers. But the cost savings from weight reduction and aerodynamic efficiencies have ended all debate. Many business jets and a growing number of airliners have made use of fly-by-wire technology. Perhaps a quick primer is in order.

— James Albright

Updated:

2023-12-15

Photo credit: Matt Birch

(http://visualapproachimages.com/)

A main character in our story is the Gulfstream GVII, that company's second foray into fly-by-wire technology but most notable because of its revolutionary "clean sheet" design. It was the first series that fully embraced electrons over hardware. They are not alone in this. I've also flown fly-by-wire aircraft by Dassault and Embraer, which were both groundbreaking in their own rights. Airbus and Boeing also have a few fly-by-wire offerings.

All of this begs the question why? The primary answer is due to weight savings. The cables, pulleys and other replaced hardware were heavy. It takes fuel to carry all of that hardware. A second reason is for aerodynamic efficiency. If you put a computer between the pilot and the airplane, you can design an airplane that is faster and with longer range but would be too difficult for a mere human to fly.

A second question is what if? What if the computers break? Designers are required to add levels of redundancy. What if someone nefarious tries to hack into those computers and take control from the pilot? While not called this in so many words, manufacturers use fire walls to isolate the flight control systems from all other communications systems or other points of access. (As the book points out, there is yet another weak point.)

Have there been problems over the years? The few examples we have available have not been catastrophic, but fly-by-wire systems have not been entirely trouble free.

Finally, there are many complications when going from "fly by cable" to fly-by-wire. While fly-by-wire systems are lighter, less prone to breakdown, and provide efficiency not otherwise available, they are hard to design, to troubleshoot, and to train.

1

Why? Weight reduction.

The evolution of flight control technology

For most of the first decades of powered flight, flight controls meant cables, pulleys, and bell cranks between the pilot's stick or yoke and the actual flight controls (ailerons, rudders, elevators, etc.) and everything was easily understood. It made intuitive sense that pulling back on the stick or yoke caused the elevator to go up, for example, due to the mechanical translation of the forces.

As aircraft became faster and heavier, however, hydraulic assistance was needed to actuate the flight control surfaces. In some cases, aerodynamic contrivances, such as Balance tabs, were needed to assist the pilot. In most cases, these systems did not replace the cables and pulleys, but added to them. Flight control systems were not only getting heavier, but they were starting to change the "feel" of aircraft control.

Partial fly-by-wire systems began to replace mechanical systems. Electronic yaw dampers and spoilers, for example, improved aircraft control and in some cases reduced the number of mechanical systems.

A true fly-by-wire airplane eliminates the mechanical systems between the pilot and flight controls. This not only greatly reduces the total weight of the system, but often improves aircraft control and allows the use of safety systems to prevent the aircraft from exceeding safe flight envelopes.

Weight savings

Replacing non-fly-by-wire mechanical systems with full fly-by-wire systems offers many weight savings:

- Fewer mechanical components. Fly-by-wire systems replace many mechanical components, such as control cables, pulleys, and hydraulic systems, with electronic components like computers, sensors and wires.

- Lighter materials. Fly-by-wire systems can use lighter materials for control surfaces since the electronic actuators used in these systems are often lighter than the mechanical systems they replace. This can lead to weight reduction in control surfaces like ailerons, elevators, and rudders.

- Improved efficiency. Since fly-by-wire system are computer controlled, they don't need to be made as robustly to compensate for a human pilot's tendency to over control.

- Integration of functions. Fly-by-wire systems can combine functions of various components to serve multiple purposes. Some FBW aircraft, for example, use ailerons on the ground to augment ground spoilers, allowing for smaller dedicated ground spoilers.

- Elimination of backup systems. True fly-by-wire systems can eliminate heavy backup systems. The electronic and mechanical boxes of a dedicated autopilot system, for example can be replaced by software in the flight control computers.

A few words from two manufacturers

Fly-by-wire means that pilot inputs don’t mechanically move the control surfaces. Instead, inputs are read by a Flight Control Computer (FCC) that decides how to move the control surfaces to best achieve what the pilot wants. The FCC’s signals are sent electrically over a wire rather than mechanically through bell cranks and pulleys. The net result is:

- Enhanced flying qualities

- Enhanced stability

- Greater protection through the entire flight envelope, Continuous monitoring

- Improved maintainability

- Simplified rigging procedures

- Built-in test capability for easy troubleshooting

Source: GVII-G500/G600 PAS, p. 6-1

The digital FBW (Fly By Wire) technology allows:

- Improved safety by:

- Preventing the airplane from exceeding the safe flight envelope while reaching maximum airplane performance,

- Allowing instinctive reaction in emergency situation,

- Reduced pilot workload by:

- Simplifying airplane handling characteristics,

- Enhancing airplane stability,

- Improved performance.

Source: Dassault Falcon 8X DODDE, p. 01-02-00, p. 4/6

2

Why? Aerodynamic efficiency.

A fly-by-wire system enhances aerodynamic efficiency in several ways:

- Fly-by-wire systems allow for precise and real-time control of control surfaces (such as ailerons, elevators, and rudders) based on complex algorithms and flight conditions. This precision helps optimize the control surface positions, reducing unnecessary drag and improving overall aerodynamic efficiency. Consider, for example, the compromise needed to position a horizontal stabilizer and its elevators. Conventional aircraft may have the stabilizer position controlled by the flaps or a mechanical trim switch, with the elevator needed to fine tune the aircraft's pitch. With a fly-by-wire system, both can be "fared" to minimize drag while still permitting precise control.

- Fly-by-wire systems can dynamically adjust control surfaces to minimize drag for varying aerodynamic loads as well as changing weight distributions. Some older aircraft use fuel management to optimize aircraft center of gravity to minimize fuel burns. A fly-by-wire aircraft can optimize flight control positions for given center of gravities to the same effect.

- Fly-by-wire systems can adjust flight controls to augment aircraft stability under a wide range of flight conditions, rather than relying on fixed external fairing to do the same for a more limited range of conditions.

- Fly-by-wire systems can go beyond conventional stall barrier devices and high speed warning horns by dynamically optimizing aircraft performance for the entire flight envelope. A stick pusher, for example, simply reduces angle of attack abruptly when the aircraft approaches a stall. A fly-by-wire low speed awareness system can actually allow the aircraft to continue flying at the lowest possible speed. Where conventional systems can be as crude as a wind vane that reacts the same way no matter the conditions, a computerized flight control system can monitor environmental and aircraft performance simultaneously to produce an optimal solution.

3

What if? Redundancy.

A common complaint in the old control by cables versus control by computers debate is that you are taking control away from the pilot. What if the computers fail? What would you do if you get the "Blue screen of death" while in flight? Each manufacturer has their own solution but they all seem to involve multiple computers, each checking each other.

One aircraft I've flown uses six Flight Control Computers, each with a combination of duties and any two of which can fly the airplane. On top of that there are two backup computers.

Another aircraft I've flown has four FCCs, two of which are active and two which monitor the other two. At any given time, only one FCC is flying the airplane as a second monitors its performance. The other two computers are doing the same, but do not actively control the aircraft. All four have to agree and when they don't, the computer(s) not in agreement get thrown out. If all that fails, a fifth backup flight control computer takes over.

With true fly-by-wire aircraft, the redundancy to a computer is another computer. There are no non-computer backups. One manufacturer retains a mechanical backup to the elevator, but that is meant to keep the airplane flying until the computers are brought back to life. You could argue that the reliance on computers is foolhardy. But several of the aircraft I've flown use hydraulic lines to control the aircraft without mechanical backups. You could make the same argument about them. What can go wrong? See Japan Airlines 123 for an example of a Boeing 747 with no active flight controls at all.

4

What if? Fire walls.

Though I am not aware of any fly-by-wire manufacturer who uses the term "fire wall," the point is that there is an impenetrable barrier between the flight control computers and associated electronics, and the rest of the airplane. I imagine regulatory agencies must spend a lot of time ensuring this is true, but as the case of two Boeing 737-MAX crashes proves, these agencies can be fooled. But the intent is clearly to keep fly-by-wire systems separate from all others.

As the book Fly by Wired points out, there is a great deal of trust placed on everyone involved in the manufacture of a fly-by-wired airplane. It is obviously in everyone's best interest to keep these "fire walls" intact. Or is it?

5

Problems? A few examples.

I don't know of any catastrophic failures of a fly-by-wire system resulting in a loss of life or aircraft, but there have been a number caused because the pilots didn't understand what was going on inside the computers. A few of note:

- In 2008, the loss of an Airbus A330 was prevented by the pilot following repeated failures of one of the aircraft’s three air data inertial reference units. More about this: Qantas 72. The software has been updated as a result.

- In 2009, an Airbus A330 crashed into the Atlantic Ocean because the pilot's didn't understand how to fly the airplane at high altitudes without the automation working properly. More about this: Air France 447.

- In 2014, the crew of an AirAsia flight lost control in flight after performing an unnecessary reset of its flight control computers when reacting to a non-critical problem with a rudder system. More about this: AirAsia 8501.

- In 2020 and 2021, two Gulfstream G500s experienced hard landings when improper pitch inputs caused the airplane to go into "AOA limiting," whereby the flight control computers limit pilot control authority. While both incidents were due to pilot error, the aircraft reacted differently than expected. The software was updated to prevent recurrence.

Two things to be said about this list. First, I've heard anecdotes about many more incidents and you can argue that many famous accidents are related to aircraft that are not fly-by-wire but were caused by problems with electronic systems which had fly-by-wire similar systems. The most notable example is with the Boeing 737-MAX. More about this: Lion Air 610

Secondly, many fly-by-wire accidents and incidents have more to do with the pilot than the computers. Pilots who believe that all aircraft fly alike are mistaken.

6

Complications? Design, maintenance, and pilot education hurdles.

It has been my experience that aircraft manufacturers do not publish complete information on how their fly-by-wire systems work, trainers do a poor job of teaching these systems, and most pilots of fly-by-wire aircraft only have a rudimentary understanding of what goes on between their cockpit controls and the actual flight controls. As we've seen with several accidents and incidents, fly-by-wire aircraft do not fly "just like any airplane" and require more from their pilots.

It may also seem alarming that even after years and years of trouble free service, many fly-by-wire aircraft can surprise their designers with unpredicted behavior. I wonder also about the level of scrutiny placed on the designers and builders of these very sophisticated systems. As I hope to have shown in the fiction that is Fly By Wired, these systems can be corrupted from the start.

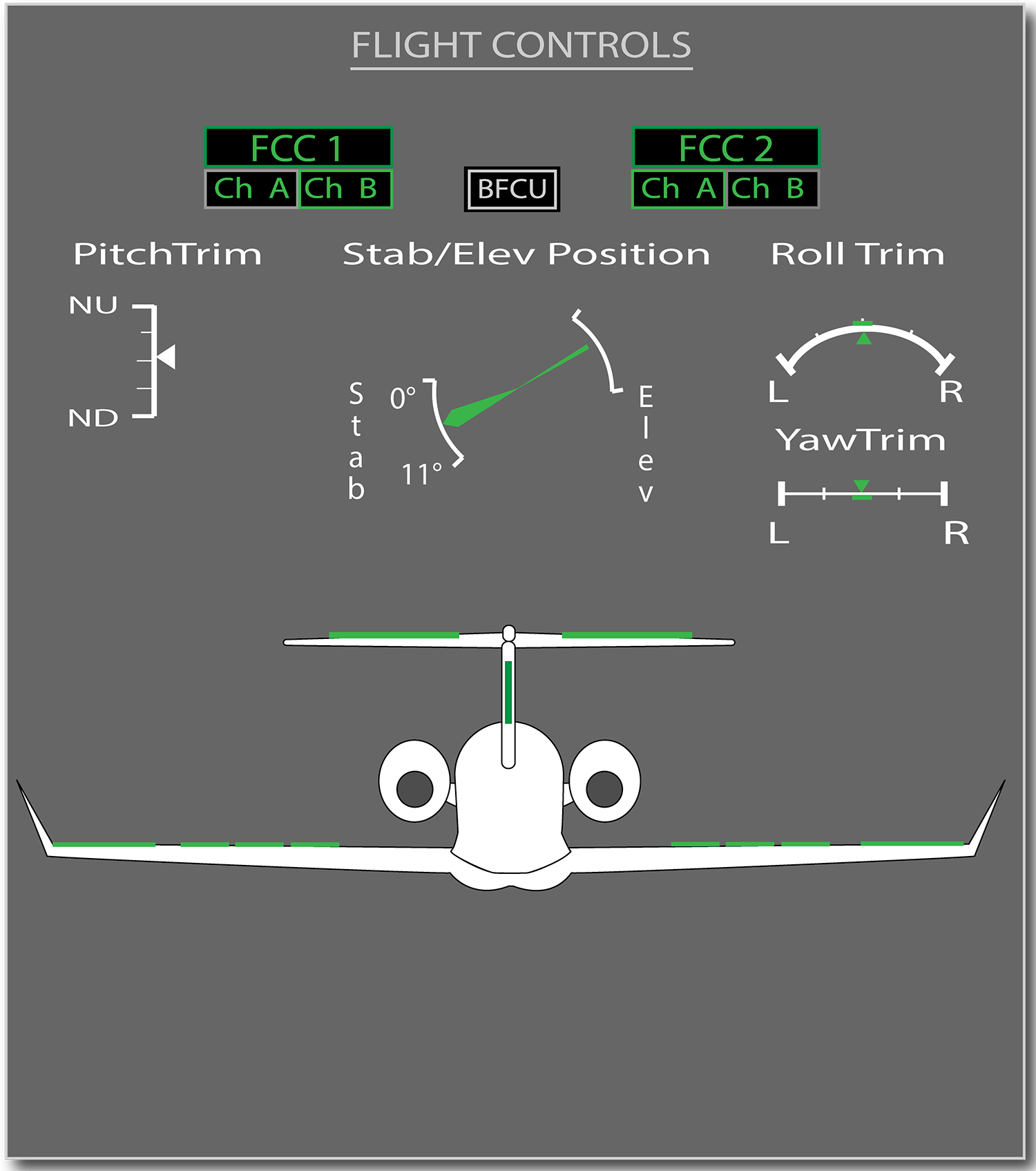

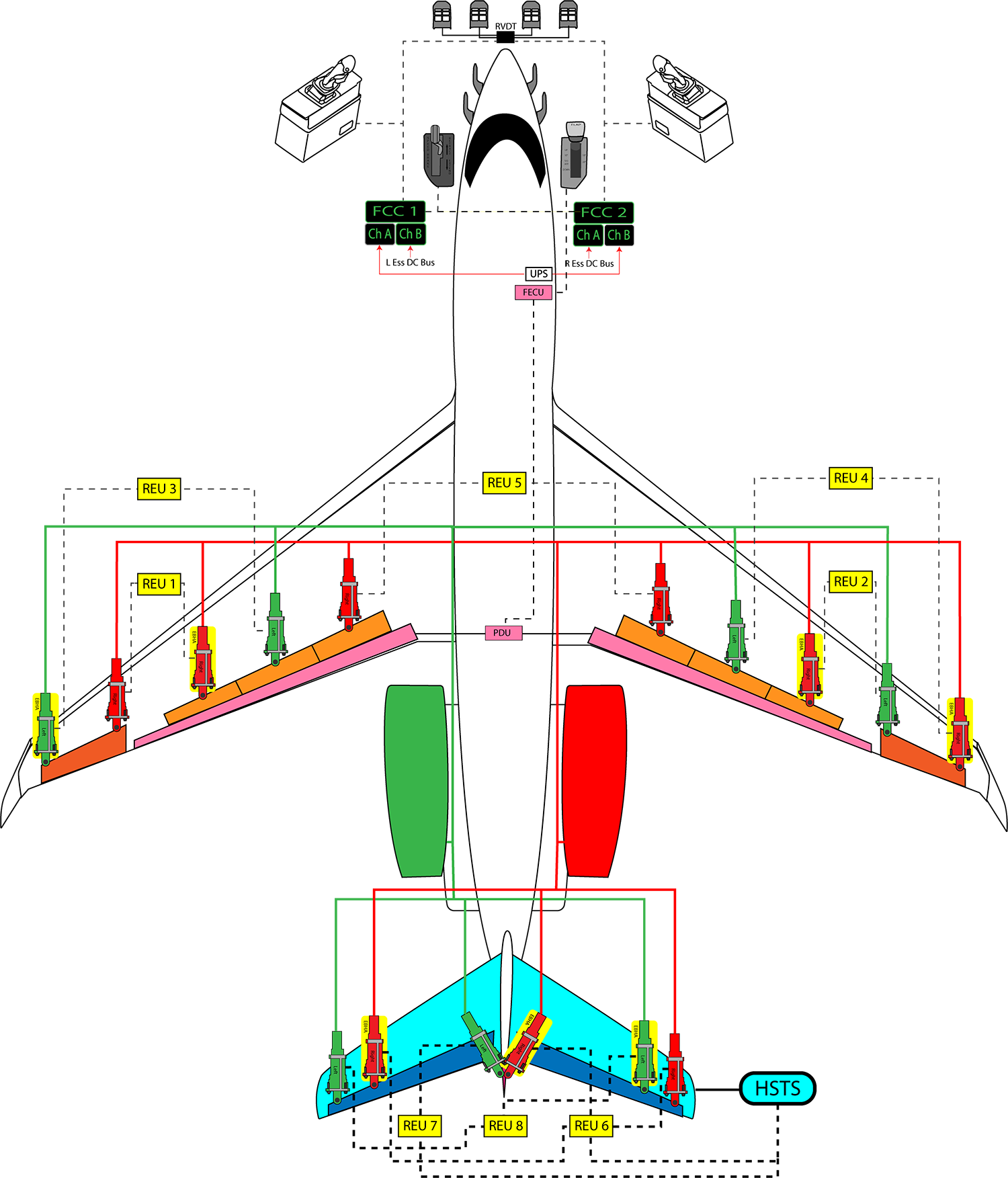

Here is Part 1 of a three part series on the GVII fly-by-wire system. This is just the basics, and as you will see, even the basics can be very complicated.

References

(Source material)

Falcon 8X Crew Operational Documentation for Dassault EASy (CODE), Dassault Aviation, Revision 04, September 10, 2020.

GVII-G500/G600 Production Aircraft Systems (PAS), Gulfstream Aerospace Corporation, Revision 9, Feb 8/22

Please note: Gulfstream Aerospace Corporation has no affiliation or connection whatsoever with this website, and Gulfstream does not review, endorse, or approve any of the content included on the site. As a result, Gulfstream is not responsible or liable for your use of any materials or information obtained from this site.