The idea that we have become too reliant on automation and have let our basic stick and rudder skills atrophy isn't new. Every few years there is a noteworthy crash, hand wringing, and the call for pilots to take a little more stick time. This has been around for almost as long as I have been flying. But I don't think more stick time will answer the problem. What we need is better stick time, hand-flying the airplane when it is safe to do so and then do so in a way that helps us improve.

— James Albright

Updated:

2019-01-11

I have to admit I am guilty as the next pilot, even back in the days when the only automation involved was a flight director. My first flight director was in the Northrup T-38 and I remember once watching in fascination as the needles seemed to align themselves, as if there was an autopilot. (There wasn't.) Then I realized my eyes and hands were simply reacting to the cross bars of the flight director and I hadn't looked at the raw data since the course and glide slope were captured. That was in 1979.

Whenever I hear of an airplane that has crashed because its pilots gave up control to the electrons, I think of that day in the T-38. The tendency is natural, your brain seeks the easy way out and would rather be a passenger when the autopilot seems to be doing a flawless job. This, of course, is a recipe for disaster. But you can beat it by mentally flying the airplane even when the electrons are handling the stick and rudder. That way, when the electrons mess up, you will be fully prepared to take over.

2 — The problem: the proficiency of our "hands"

3 — The problem: disengaged brains

4 — The problem: inadequate autopilot monitoring skills

5 — A possible solution: more stick time

1

The problem: ego

We pilots like to have control of whatever situation we are in and tend to believe we have that control. Our egos give us this arrogance and that is a good thing: you have to believe before you can be. I have the added baggage of being an engineer. We engineers believe that if we have as many formulas as we have variables, we can solve the formulas. That's another form of arrogance because sometimes there are variables hidden from our view. But both pilots and engineers should understand that not everything goes according to plan, even if we believe.

I have to relearn this lesson over and over again. Here's an example. The movie "Superman" came out around Christmas time in 1978 and was a critical and commercial success. Many say that this movie gave birth to a genre of superhero films that has lasted to this day. There is a debate on who is the better superhero, Batman or Superman. Regardless of where you fall in that debate, the movie Superman paved the way.

We saw this in a theater when it was the number one box office hit. I had graduated earlier that year from Purdue University with a degree in Industrial Engineering. I was still a month away from starting Air Force pilot training. I had read the comics as a kid and was enjoying the movie until this scene. Lois Lane is falling from atop the Daily Planet office building to her certain death. Superman changes into his tights and soars up to catch her. (Video: Superman Catches Lois) At that point I said, too loudly I guess, "Now she's twice as dead."

My fellow movies goers didn't appreciate that.

Well, as it turns out, I wasn't as smart as I thought I was. I didn't figure that only falling half the distance her velocity would be reduced almost by the factor of Superman's velocity upon arrival halfway up the building. So she isn't twice as dead, she is slightly more dead. (260 G's in Superman's arms versus 250 G's on the pavement.) If you would like to see the math, here it is: Defying the Laws of Physics.

2

The problem: the proficiency of our "hands"

Even without an engineering degree, if you are an instrument rated pilot you will need a pretty good understanding of what the electronic gizmos are doing behind the scenes. These days, most autopilots and flight directors are digital, meaning they are controlled by computers. So now you have to understand software as well as hardware.

To better understand how the automation has eroded our stick and rudder skills, you need to trace the evolution of that automation to where it has become thought of as better than human. Only then can you realize that the problem with modern automation is that failures are unpredictable.

Back then . . .

Autopilots have been around since 1930, when they basically kept the wings level, the nose pretty much level, and little else. These early efforts were little more than gyroscopes mechanically connected to ailerons and elevators. More about this: Now - The Automatic Pilot, Popular Science Monthly, Feb 1930.

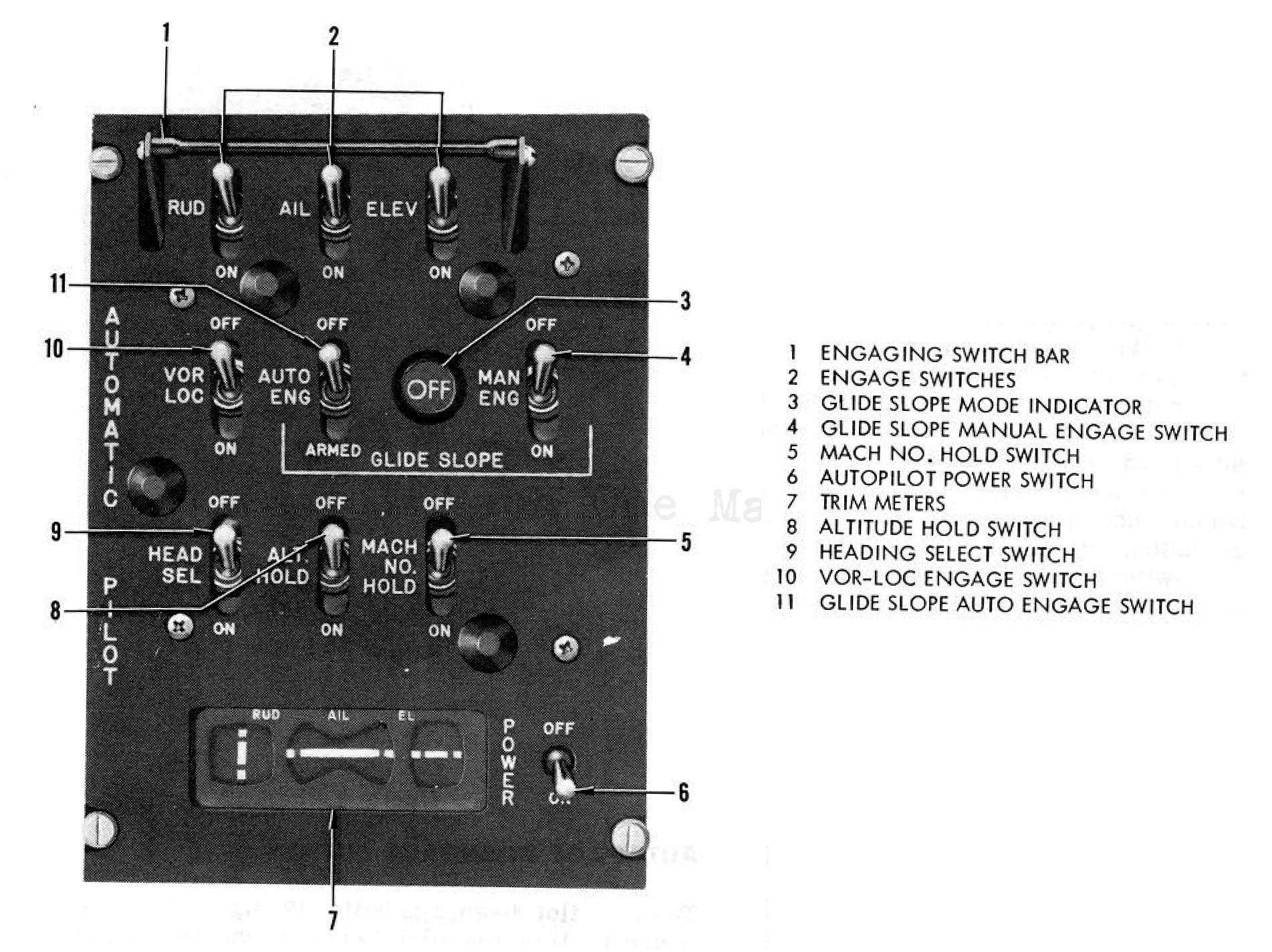

KC-135A Autopilot, 1C-135(K)A-1, figure 4-40

My first autopilot was in the KC-135A tanker. The system I flew in 1979 had been around at least since 1966 (when the manual was written) and stayed on the airplane until the entire avionics package was changed in the 1990s. Looking at the panel, you will see some strange things and some that are familiar.

First the strange. There was a power switch so you could shut it down, you engaged one axis at a time, and there were meters to show you how much pressure each axis of the autopilot was applying. Even the designers realized their contraption was likely to misbehave and the human pilots would need to be able to turn the thing off in sections or completely.

But now, the familiar. It looks like the system had the ability to maintain a course (VOR/LOC) and fly vertically (GLIDE SLOPE, ALT HOLD, and MACH NO. HOLD). We never used them. In fact, the only thing we did with the autopilot was to engage it during cruise using HEAD SEL and ALT HOLD. The ALT HOLD was a critical thing for a tanker; you had to maintain a stable platform for the receivers. So it maintained a heading and held our altitude. We didn't trust the autopilot beyond those simple tasks.

I only flew this airplane for two years. By virtue of the fact I flew it out of Loring Air Force Base, Maine, I flew it down to minimums many times. But each of those approaches was hand flown. We couldn't trust the airplane to do that for us. Not only did that mean we had to stay proficient, but that we had to keep an eye on our limited automation.

Not too long after . . .

My next autopilot was in the Boeing 707 which had the same issues as that in the KC-135A. But after that I got to the Air Force version of the Boeing 747 where the autopilot, at the time, was state of the art. It replaced the vacuum tubes with computers and now we had something that could reliably track a course, climb, descend, and even land. Our 747 (E-4B) was air refuelable and that was about the only maneuver we had to hand fly; the autopilot could do just about everything else. We were even trained for Category IIIA ILS approaches, which had to be coupled.

I have to admit that I hated those. Practicing a coupled approach in good weather was worse than flying in the weather to minimums because the approach area wasn't sterilized when the weather was okay. There are few things in aviation more startling than to be flying a coupled approach in a Boeing 747 when a truck drives through the localizer signal just as you hear the radio altimeter say "fifty, forty, thirty," and so on. But even without that excitement, the autoland was hit and miss. Some days it would be on speed, in the touchdown zone, with a very nice touchdown. The very next landing could be a bone jarring experience on brick one or halfway down the runway. We trained with United Airlines and after they got their first Boeing 767s I heard something startling. Their rules required the airplane demonstrate an autoland once every 90 days. Boeing 747 pilots would pencil whip the event because they didn't want to give up a landing and they didn't want to subject their passengers to one of those bone jarring events. At the same time, their Boeing 767 pilots were giving the autopilot more landings than they would take, because it did such a good job of it.

All of this happened in the 1990s. It appeared we had crossed a line in aviation. We had come to the point that the automation could do a better job than we humans under most conditions. For some crews, this meant "George" had the airplane from takeoff to landing. We pilots became computer programmers.

And that brings us to today . . .

Singapore Airlines 327, aircraft position after stop, BFU EX010-11, p. 26

My only experience with an automatic landing system (autoland) was in a Boeing 747-200 in the 1980s. Even under ideal conditions, the system's performance was inconsistent. Some days it would kiss the runway in the touchdown zone and all we had to do was deploy the thrust reversers and steer with our feet during the roll out. Other days it would miss the touchdown zone and land so hard you needed to schedule an appointment with the dentist to check your fillings. But the worst of it was when practicing an autoland in good weather, days where the tower would not "sterilize" the ILS critical areas. I once watched the system perform flawlessly until the throttles came back and the nose came up during the flare, when suddenly the ailerons dipped our 200 foot wingspan to one side with only 20 feet of altitude. I disengaged the autopilot and took over manually.

I hear that newer Boeing autoland systems are so good, pilots are reluctant to manually land since "George" routinely makes them look good. But they still have the problem with interference from airplanes or ground vehicles getting in the way of the localizer signal at the worst possible moments. That is precisely what happened to the crew of Singapore Airlines Flight 327 in Munich Germany, on November 3, 2011. Their operator recommended the use of autoland with cloud bases at or below 500 ft AAL or with visibilities of 2 km or less. But under the rules in place in Munich, the ILS critical area did not have to be protected until the visibility was far worse. The pilots were not sufficiently paranoid of the system and did not let ATC know they were using the autoland system. Further, they failed to fully take over the moment the system misbehaved. More about this: Singapore Airlines Flight 327.

3

The problem: disengaged brains

There are a lot of good reasons for letting the autopilot take care of the mundane tasks, such as getting your airplane down to minimums, while you reserve your talents to the thinking part of the game. Sure, you could do the stick and rudder, but you also need to be thinking about the logistics of the flight. You have to make the decision to land or go around. That is the way it should be. But as the human "Pilot Flying" you need to become the human "Pilot Monitoring" since the actual flying is being done by the electrons. If you fail to do that, it will become a habit. And that means you have become a passenger.

I started flying the Gulfstream GV in 2005 and had only a few complaints about its autopilot. The G450 I am flying today has basically the same system but has somehow become worse. The autopilot tends to over-correct in the climb when holding a target speed, the autopilot's altitude capture system can become confused if the altitude select is changed after capture, the turn rate for a lateral capture can be erratic, and the thing seems to overshoot an approach course now and then. But once it has the course captured, the autopilot flies a very nice ILS, LNAV/VNAV, or LPV approach. Better than I can.

In fact, with the airplane's infrared and Heads Up Display systems, it can do a lot of things I cannot. Here's an example approach to minimums: Down to minimums.

I have been flying jets for almost 40 years now. (In fact, as I write this, I am one month shy of that milestone.) It is tempting to think that I have more approaches to minimums than I can remember, I don't need any more stick time. I'm good, I sometimes tell myself. But I am not proficient, I often find out. Every six months I hand fly a few approaches to minimums in the simulator and have never had a problem. But is that good enough?

Since we are talking about six months, here is a list of mistakes I have made flying instrument approaches in the last six months:

- I overshot the KTEB ILS 19 localizer; well, the autopilot overshot it but I didn't catch it until it was too late.

- I landed well right of centerline after taking over from the autopilot's KBED ILS 29; the airplane was crabbed into the wind at 500 feet, I kept the crab in but the wind died.

- I just barely achieved stabilized approach criteria at 1,000 feet on final to the MMTO ILS 15 after we were "slam dunked" into the high elevation airport. We broke out at 2,000 feet AGL but our company rules require a stable approach by 1,000 feet on any straight in, even when VMC. Knowing this I kept the speed brakes with Flaps 20° longer than I should have. I managed to get the boards stowed prior to glide slope intercept, then the gear. I didn't get the flaps until just over 1,000 feet AGL which meant we were a "bit" fast. I landed on speed, on centerline, in the touchdown zone. But it wasn't an approach I would brag about.

- I flew a visual approach using the KIAD 01C ILS as a back up, ended up a dot high for most of the approach until the other pilot said, "you are a little high." I finally corrected, but I needed the reminder.

We get used to the automation making us look good and we get lazy. We aren't as quick as we need to be with corrections when the automation makes a mistake. (Case 1) Even when the automation does a good job and it is our turn to fly, we aren't always in tune with the situation and do a less than graceful job taking over. (Case 2) When it is obvious the situation will be beyond the automation's capability to cope, our efforts aren't always much better. (Case 3) We often take credit for flying an instrument approach as a back up to a visual, when in fact we are doing nothing more than looking out the window and letting the needles slide. (Case 4)

Or course these all seem like minor transgressions. In each case we landed and nothing bad happened. Things can be much worse when the human element fails:

- Air France 296 — The Airbus philosophy in automation design tends to override pilot inputs more often than other designers. Airbus pilots should have a good understanding on when this happens. In the case of this 1988 air show the pilots didn't fully appreciate that once their autothrottles had retarded for landing, there was very little they could do to get any thrust back.

- Asiana Airlines 214 — There are more than a few airlines out there with pilots who cannot seem to fly a visual approach. Airlines flying large, long-distance airplanes are especially vulnerable, since their pilots almost always end each flight with a solid, reliable ILS. The pilots of Asiana Airlines Flight 214 had some difficulty when the ILS glide slope was out of service at KSFO on July 6, 2013.

- China Airlines 006 — There is one defining characteristic of a multi-engine pilot versus a single-engine pilot, at least there should be: an acute awareness of yaw. Some autopilots are smart enough to add some rudder on takeoff. Very few can do this during cruise flight. No matter the flight regime, it is the human pilot's responsibility. On February 15, 1985, the captain aboard this Boeing 747 failed to apply any rudder after an engine failure at 41,000 feet. The aircraft rolled itself onto its back and the captain was unable to recover until they popped out of the clouds at 10,000 feet. The press initially lauded him as a hero. He was not.

- Korean Air 801 — There have been more than a few cases of airlines from Korea crashing because their pilots could not bring themselves to flying without an electronic glide slope. On August 6, 1997, the captain of this Boeing 747 flew something (but not an ILS glideslope) right into the terrain short of the runway at Guam's Won Pat International Airport.

- Lion Air 904 — Yet another case study of a crew flying some kind of glide path where there was no electronic glide path. On April 13, 2013, this Boeing 737 crew had the good sense to land in a lake, limiting the damage to one airplane.

- Turkish Airlines 1951 — On February 25, 2009, Boeing 737 was destroyed and 9 people killed because of a faulty radio altimeter. No, that's not right. This airplane crashed short of Amsterdam-Schiphol International Airport because the crew failed to monitor their automation, which became convinced it was time to pull the throttles for landing while still at approximately 2,000 feet.

- United Parcel Service 1354 — The first time I was ever critiqued for failing to ensure my FMS had properly sequenced for an approach I thought the complaint was overblown. What could go wrong? What indeed. On August 14, 2013, this crew failed to notice their Airbus A300's FMS had a discontinuity that prevented their vertical path information from displaying. The pilot then selected Vertical Speed Mode, turning the approach into a "dive and drive" but the dive was to a DA meant for closer to the runway.

Fatigue played a role in many of these accidents. The calls for "more stick time!" might have helped, but I think hand-flying in some of these situations would have made things worse. In fact, there are times when hand flying just for proficiency is the wrong answer.

4

The problem: inadequate autopilot monitoring skills

The automation is better than the pilot at many things and should be the obvious choice for maintaining very precise control of the airplane down to minimums on an instrument approach. Better than the pilot, but not perfect. Just as you would watch a brand new copilot very closely, you should do the same with those electrons.

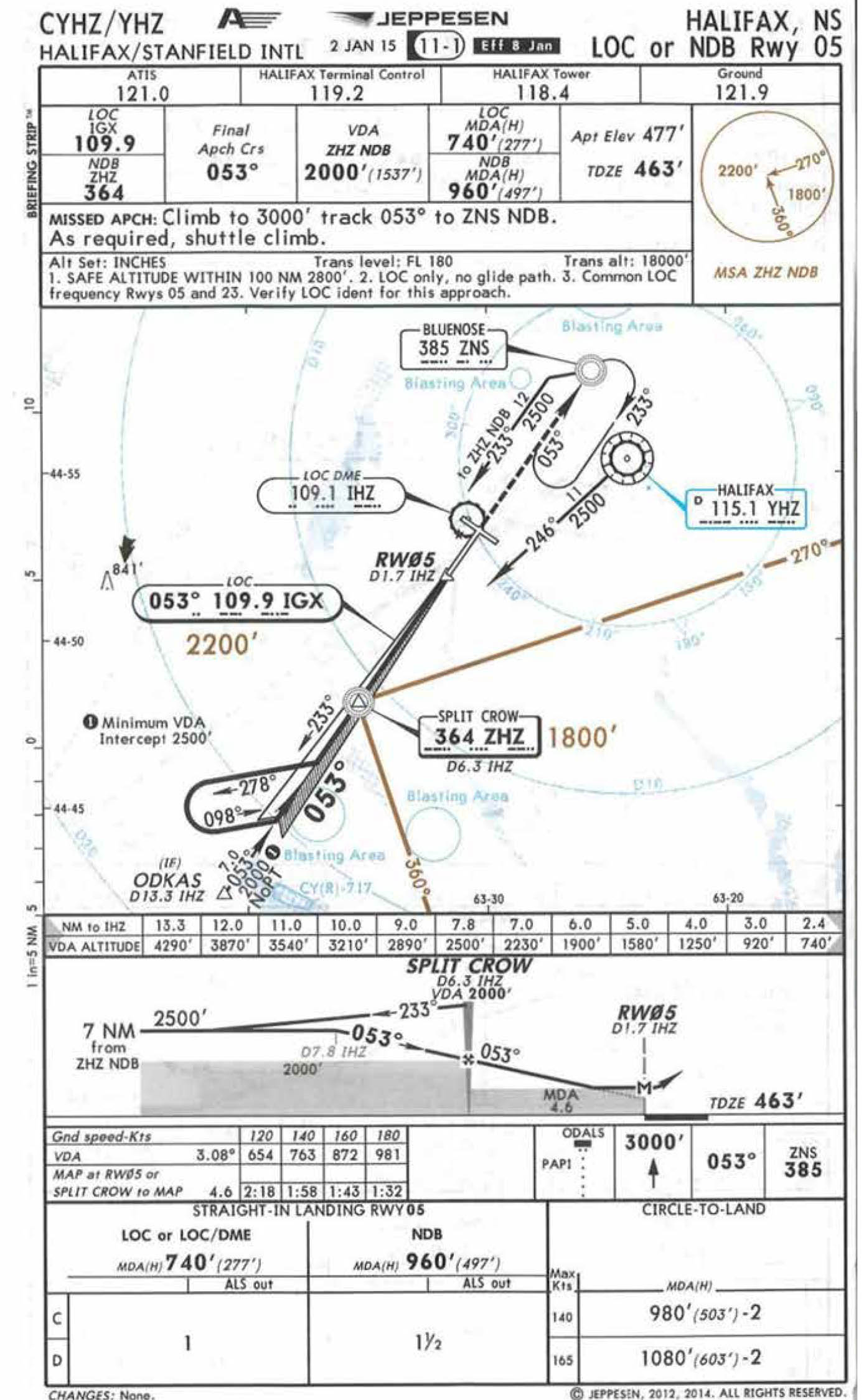

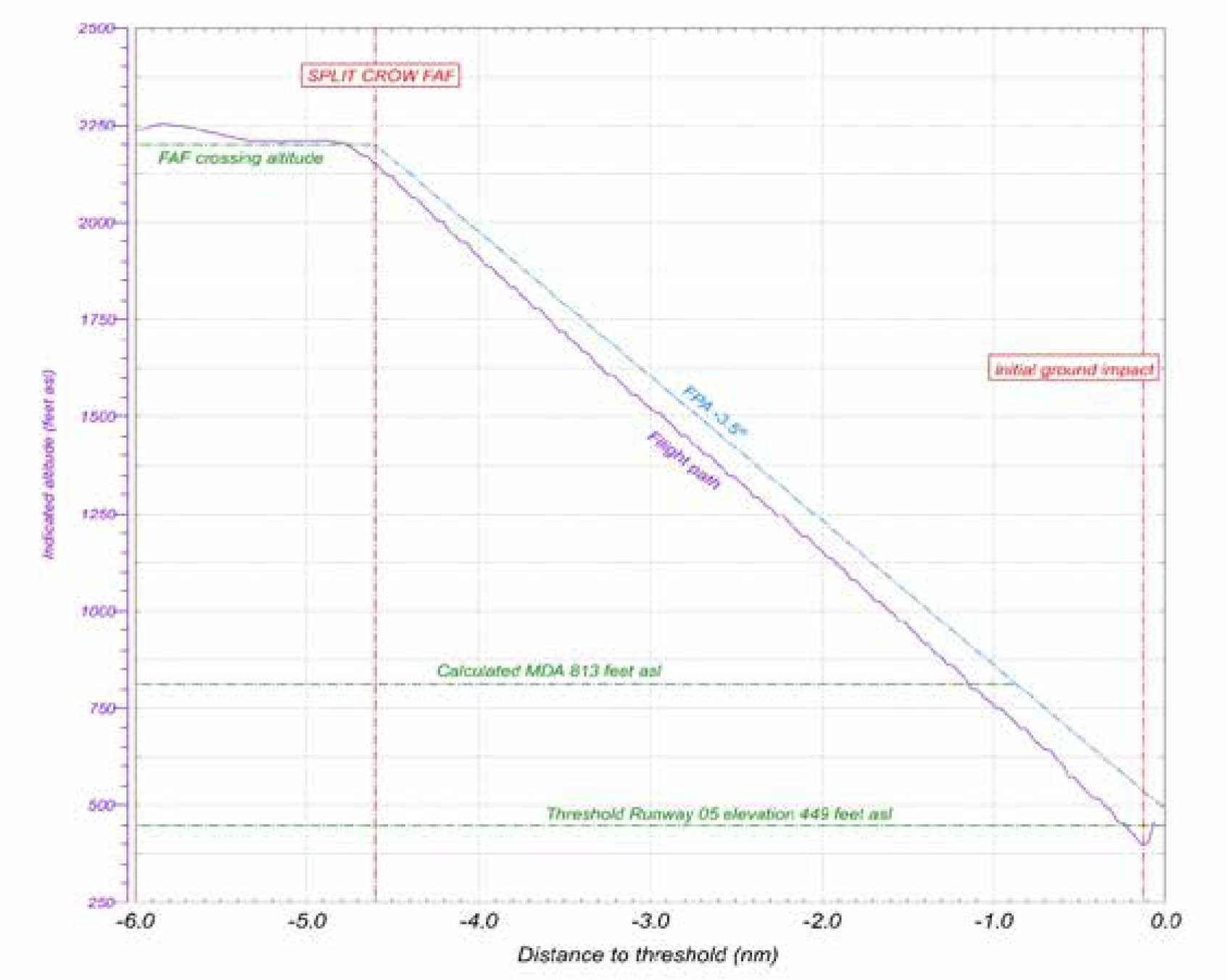

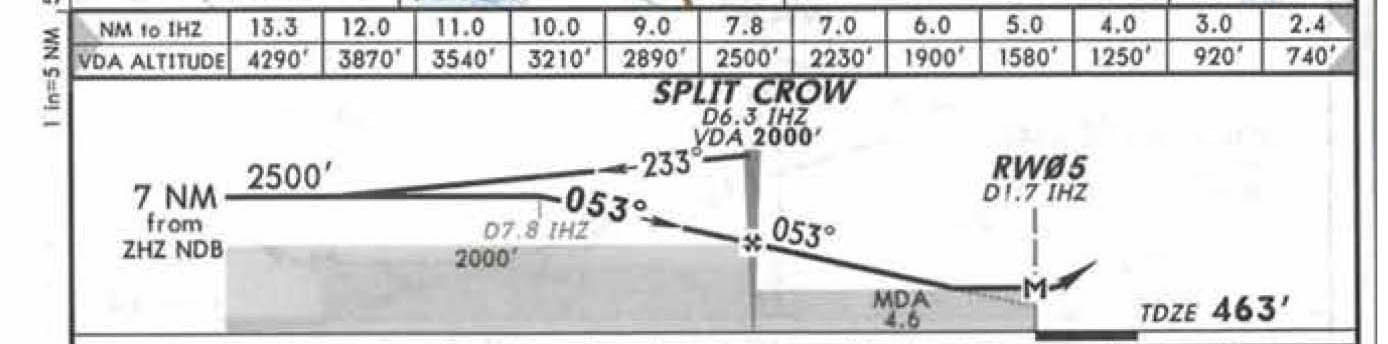

With many of the accident case studies I come away thinking the pilots were not as sharp as they could have been, but not so for this one. This is about Air Canada Flight 624 flying into Halifax, Nova Scotia, on March 29, 2015. Reading the report, I was impressed several times by the professional conduct of the crew. They were flying an A320. The temperature was minus 5 degrees, it was windy, and the visibility was just a half mile in blowing snow. Their Ops Spec allowed them to shoot the approach at ½ the visibility minimum, provided the approach is coupled. They figured the cold temperature corrections and came up with a starting altitude of 2,200 feet going down to an MDA of 813 for a continuous descent. They planned on using their autopilot’s FPA, fight path angle and they even computed the correct angle of 3.5 degrees to allow for the start from a higher indicated altitude. Not only was all their planning by the Air Canada book, but so were their briefings and callouts. In fact, they only made two mistakes. The first was so minor, I think most of us wouldn’t give it a second thought. The second was something that could have gotten any of us. So that was their plan: start their descent from 2,200 feet, use an FPA of -3.5 degrees, fly it coupled until the MDA, spot the runway, and land.

Approach chart, Aviation Investigation Report, A15H0002, Appendix A.

Air Canada procedure was for the pilot to select FPA and leave it at zero degrees when 0.3 nm before the final approach fix, and that is what the captain did. His first mistake was that he started his descent 0.2 nautical miles early. O.2 nm doesn’t seem like much. In fact, he crossed the final approach fix just 30 feet below his temperature corrected altitude. But there is a problem. The approach is designed to aim the airplane at the touchdown zone, about a thousand feet down the runway. O.2 nm comes to 1,215 feet, so the airplane was actually aimed two hundred feet short of the runway. Notice also that the gap between where they were and where they should have been is increasing as they get closer to the runway, more about that in a minute. Their early descent combined with the increased gap meant they arrived at the MDA 1,883 feet early. And, as you can see from their ground plot, they continued that descent right through the MDA and ended up short of the runway.

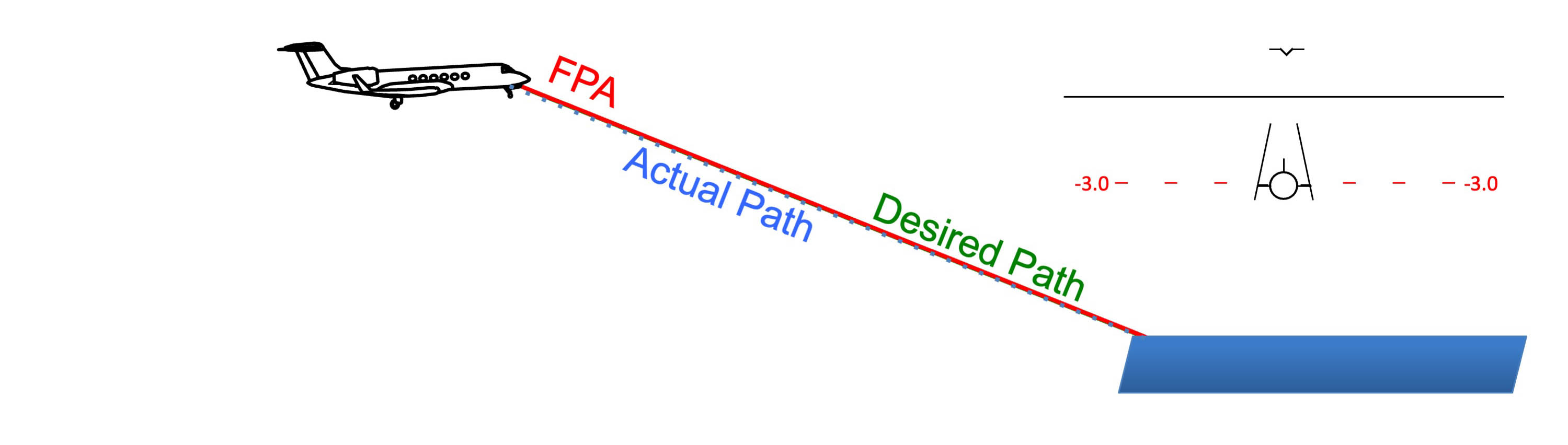

FPA versus aircraft flight path, Aviation Investigation Report, A15H0002, fig. 1.

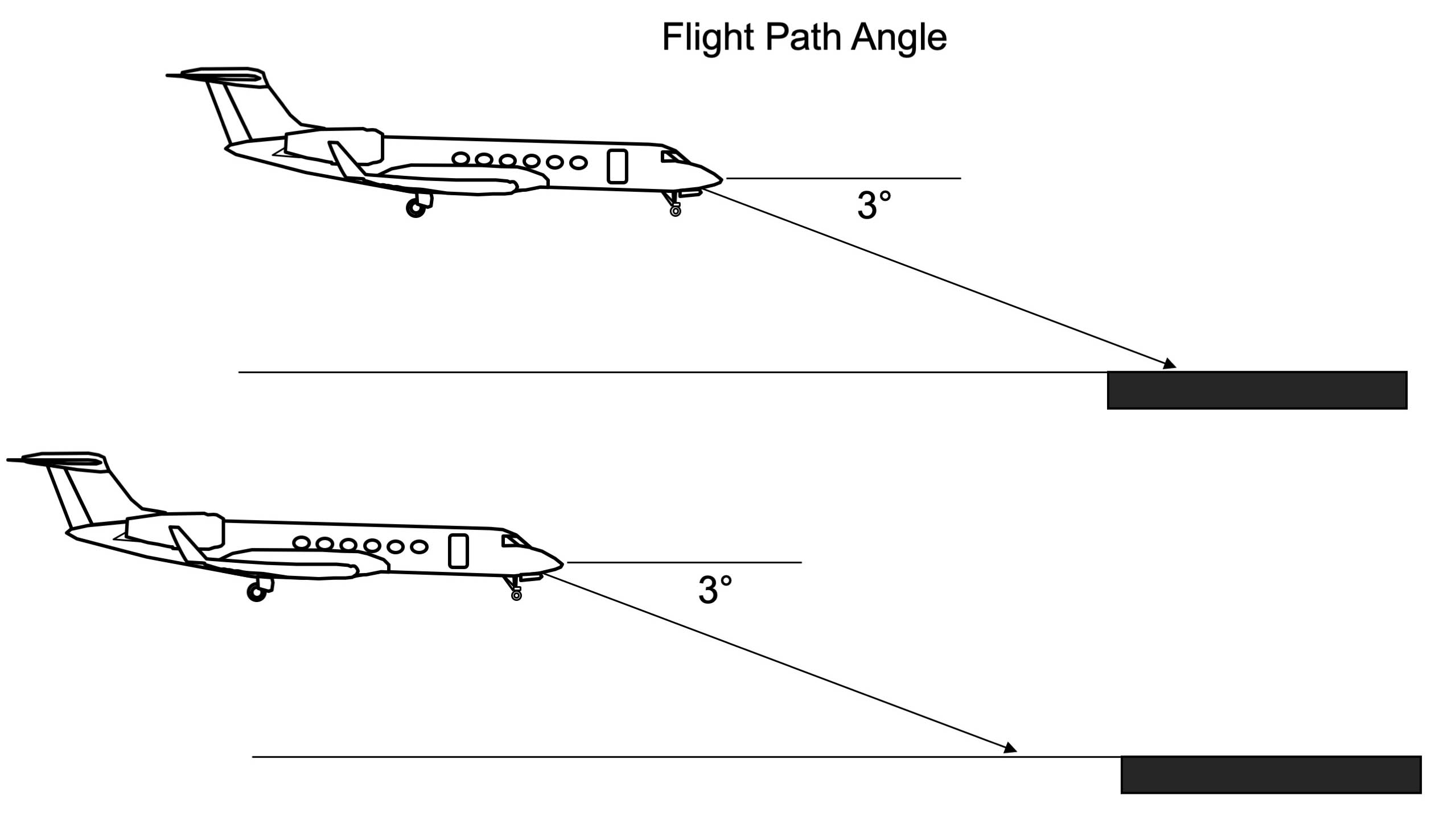

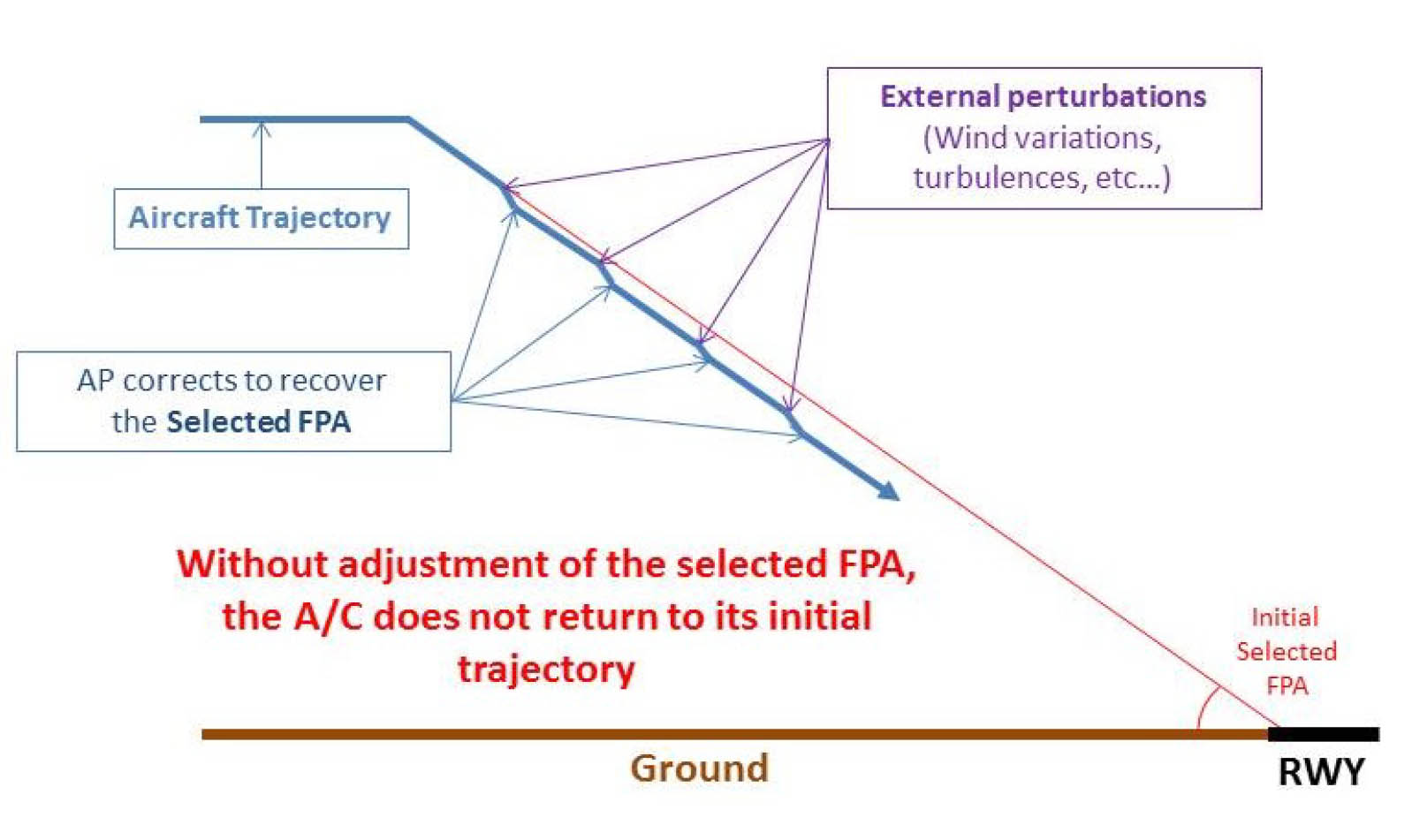

The reason the gap between where they were and where they should have been is an important point to understand if you use Flight Path Angle. The important point is that the angle is drawn from the airplane down, not the ground up. What the accident report calls external perturbations are variations in winds, turbulence, or the catch all etcetera. Whatever that perturbation does to you, the autopilot draws a new line and that line could be lower. The system doesn’t care where you originally aimed, all it cares about it returning to the selected angle.

FPA affected by perturbance, Aviation Investigation Report, A15H0002, fig. 15.

That didn’t end well for Air Canada 624. The airplane struck the approach lights, a landing gear was torn off the airplane and hit an elevator and the airplane became unflyable. Nobody was killed but there were injuries. The second mistake the crew made was that when they saw the approach lights, they assumed they were in the correct position. With a half mile visibility, they should have seen the runway ahead of them based on a 3 degree glide path. The fact they were about 1,900 feet behind where they should have been, changed the angle of the lights to just over 2 degrees. Can you tell the difference? I don’t think I can. If I thought the automation was doing a good job of keeping me on a glide path to the runway, I think I would have left it engaged until a hundred feet or so. The fact the FPA let them down surprises a lot of pilots, so let’s look at that.

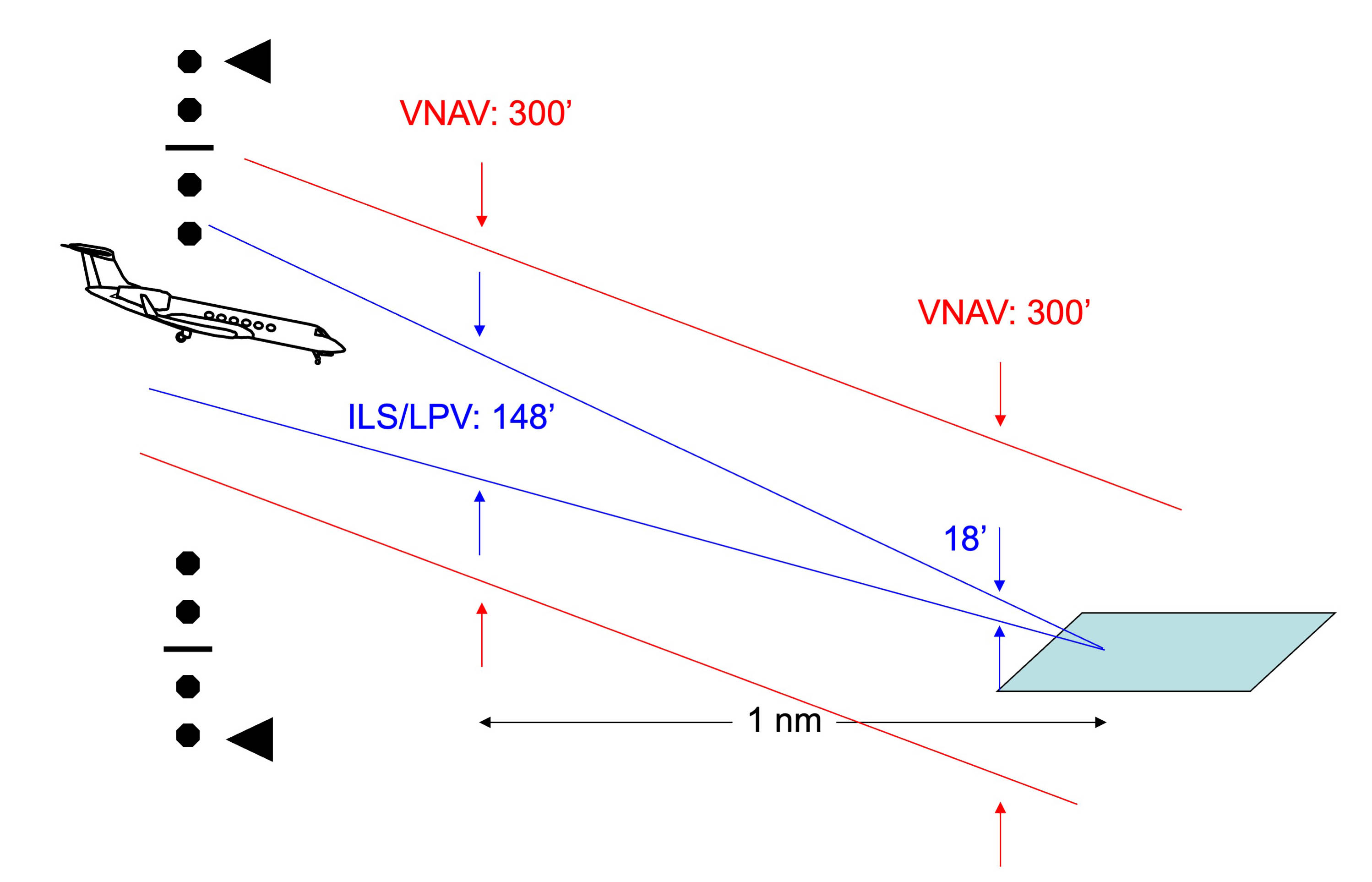

When you fly an ILS, you know there is an antenna abeam the touchdown point and if you keep the needles centered, that is where you end up. The same is true of an LPV, without the antenna. In both cases, the tolerance narrows as you get closer, just the way you want it. When VNAV came out, it was tempting to think of it as another ILS, but we soon realized that the VNAV tolerance doesn’t narrow. Flying the VNAV needle centered does get you to the runway, but riding that 2 dots low will come up well short.

Flying an FPA is entirely different animal. The FPA can get you to the runway, but it can also get you very short. As we saw with Air Canada, the other end of the FPA can also change. There are two easy solutions to this problem, but you have to know about them.

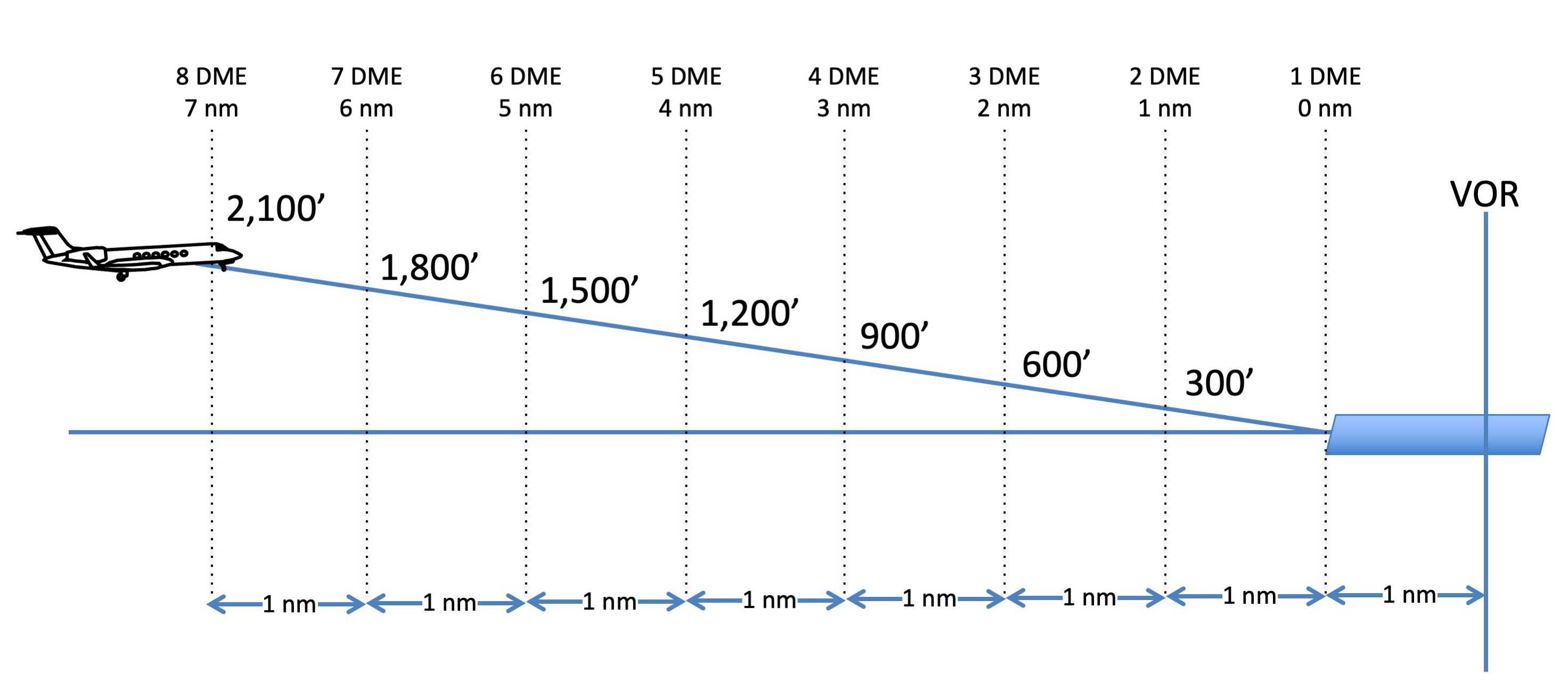

This is the oldest trick in the book from the days when having an ILS was the only option for vertical guidance to the runway, and you didn’t always have an ILS. You simply cross check altitude versus distance to the runway. A 3-degree glide path comes to 318 feet per nautical mile. Being pilots, we prefer 300 feet to a nautical mile. That works too. Back in the old days, I would figure this out before the approach. Let’s say you have a DME 1 nautical mile beyond the touchdown zone. I would figure a target altitude for each DME out to the final approach fix.

In the case of the approach into Halifax, the crew had access to just such a table on the approach chart. Air Canada SOP didn’t require their crews do this back then, but it does now. If you are flying an approach without vertical guidance, you should adopt this technique. But isn’t an FPA vertical guidance? I would say an FPA by itself is not.

Approach chart VDA altitudes, Aviation Investigation Report, A15H0002, Appendix A.

If you have a Flight Path Vector, an FPV, then you can turn that Flight Path Angle into something really useful. In this case, the FPA is the red line, aimed short of the runway. The HUD symbology on my airplane would draw that -3.0 dashed line for me, short of the runway. That by itself is an improvement. But even better, the HUD draws a Flight Path Vector, that’s the circle with the small wings and tail drawn on it. The FPV shows that not only is the angle short of the runway, but that’s where we are headed. The technique here is to “walk the FPA to the runway,” by raising our nose so the FPV goes beyond where we want to land, once the FPA is over the touchdown zone, we lower the nose to agree with the FPA. I’ve met a lot of Gulfstream pilots who prefer to fly without the HUD and they are missing out on one of the greatest safety innovations in their cockpits.

More about this accident: Case Study: Air Canada 624.

5

A possible solution: more stick time

The FAA wants you to hand-fly more often, really. But they also want you to be careful and apply good judgment. And if you break anything (or anyone), well that's you not applying good judgment. I'm not sure I agree with this philosophy.

[SAFO 17007: Manual Flight Operations Proficiency]

An air carrier’s line operations policy should permit and encourage manual flight operations and should incorporate the following:

- Encouragement to manually fly the aircraft when conditions permit, including at least periodically, the entire departure and arrival phases, and potentially the entire flight, if/when practicable and permissible.

- When deciding to fly manually, crews should apply basic threat and error management principles and take into account the various factors affecting operational workload. Factors to consider include:

- Weather conditions, terrain, and/or other environmental threats

- Time of day

- Psychological and/or physiological factors

- Level of crew experience

- Traffic density

- Condition of the aircraft, and/or any non-normal conditions

- Air Traffic Control and/or instrument procedural challenges

- Any other operational threats

- Allow pilots to conduct manual flight with all approved combinations of automation based on aircraft equipage, e.g.,

- FD on, AP off, AT on

- FD on, AP off, AT off

- FD off, AP off, AT off

- FD on, AP on, AT off

- A clear statement that the pilot in command (PIC) must use good judgment to consider the factors described above and to decide, on a case-by-case basis, when it is appropriate to conduct manual flying.

There I was . . .

. . . Our Gulfstream had done a great job intercepting the localizer and once the glide slope had centered, we started down. We were fully IMC and expected to remain so until about 700 feet above the town of Lalysos, just a few miles west of the Rhodes, Greece airport. Seven hundred feet is practically VFR in our world, so nobody was worried about the approach. I was in the right seat and had only one item left on the checklist, the final notch of flaps. We had intercepted the glide slope at 2,500 feet on the ILS 25. At about 2,000 feet the captain -- who was also the company chief pilot -- said, "Do you mind if I increase my proficiency?" Before I could answer he clicked off the autopilot and promptly got us above the glide slope needle that was, moments ago, centered. "A dot high and going higher," I said. We popped out of the weather a dot and a half high and too fast to extend our last notch of flaps. "Well I might be too high," he said, "but at least I'm too fast." The runway was over 10,000 feet long and he managed to save the landing, if not the approach.

That was one of my first times sitting in the right seat with that captain and I was, to say the least, surprised. I have messed up my share of approaches over the years but I've never been so cavalier about it. Unfortunately, he repeated this trick often.

We were flying into a very short runway and the weather was just a hundred feet above minimums. When the weather is that crummy and you have a good autopilot, like we did in this airplane, you let the airplane fly while you watch it like a hawk. That's what I do.

"Do you mind if I increase my proficiency?" he asked. The needles were centered, we were at 1,600' MSL and our DA was 400' MSL, just 200' above the terrain.

"I would rather you didn't," I said. But it was too late, he clicked off the autopilot.

"Going high," I said. "A dot high," I repeated. "You need to correct," I said. He did not. I repeated myself. He started to increase his vertical descent rate.

At decision altitude I spotted the runway, what was left of it.

He pushed the nose over hard and we found ourselves just beyond the touchdown zone in an instant. He planted the airplane about 1,000 feet too long but this particular Gulfstream had great brakes and we managed to roll out with less drama.

"Let's never do that again," I said.

The captain simply laughed.

I've replayed that approach in my head many times over the years since, wondering what I could have done differently. The right answer, I realize now, would have been to call for the go around the minute he deviated from our stable approach criteria. But, for the purpose of why we are here now, the takeaway is that all of this captain's stick time was for naught. Over the years I've never seen a pilot take more stick time in an automated airplane than he did. And yet his stick and rudder skills were poor. How can we fix this?

6

A better solution: purposeful practice

Most proponents of "We need more stick time!" will preach that "practice makes perfect!" But that maxim is demonstrably false. So then they tell you "perfect practice makes perfect!" But that is unachievable. (How can you practice perfectly to become perfect, if you aren't already perfect?)

Why practice itself is not enough

The problem with grabbing some stick time whenever the time permits is that it doesn't push you to improve and there may not be an adequate feedback mechanism.

- We all follow pretty much the same pattern with any skill we learn, from baking a pie to writing a descriptive paragraph. We start off with a general idea of what we want to do, get some instruction from a teacher or a coach or a book or a website, practice until we reach an acceptable level, and then let it become automatic. And there's nothing wrong with that. For much of what we do in life, it's perfectly fine to reach a middling level of performance and just leave it like that. If all you want to do is to safely drive your car from point A to point B or to play the piano well enough to plink out "Fur Elise;" then this approach to learning is all you need.

- But there is one very important thing to understand here: once you have reached this satisfactory skill level and automated your performance — your driving, your tennis playing, your baking of pies — you have stopped improving. People often misunderstand this because they assume that the continued driving or tennis playing or pie baking is a form of practice and that if they keep doing it they are bound to get better at it, slowly perhaps, but better nonetheless. They assume that someone who has been driving for twenty years must be a better driver than someone who has been driving for five, that a doctor who has been practicing medicine for twenty years must be a better doctor than one who has been practicing for five, that a teacher who has been teaching for twenty years must be better than one who has been teaching for five.

- But no. Research has shown that, generally speaking, once a person reaches that level of "acceptable" performance and automaticity, the additional years of "practice" don't lead to improvement. If anything, the doctor or the teacher or the driver who's been at it for twenty years is likely to be a bit worse than the one who's been doing it for only five, and the reason is that these automated abilities gradually deteriorate in the absence of deliberate efforts to improve.

Source: Ericsson, pp. 12-13

Introducing Purposeful Practice

Dr. Ericsson calls the efforts many of us employ to get better at something "naive practice." It is doing something repeatedly expecting the repetition alone will improve one's performance. He offers instead what he calls purposeful practice.

- Purposeful practice has well-defined, specific goals.

- Purposeful practice is all about putting a bunch of baby steps together to reach a longer-term goal.

- Purposeful practice is focused.

- Purposeful practice involves feedback.

- Purposeful practice involves getting out of one's comfort zone.

Dr. Ericsson's book, Peak: Secrets From the New Science of Expertise, further develops this idea into "Deliberate Practice" and is certainly worth reading. But the idea of "purposeful practice" is what we need to improve our stick and rudder skills in an age of ones and zeros. So let's do that.

When is "Practice" in the Aircraft Appropriate?

This is a decision you have to make based on your operation, your risk tolerance, the capabilities of your aircraft, and the experience levels of everyone involved. In my current operation, we do not fly a lot so I would say we are not as proficient as I would like. We will not accept risk, but then who really does? Our aircraft, a Gulfstream G450, is highly capable but the automation does not include autoland or autobrakes. All of our pilots are highly experienced. I am the pilot in charge so here are the decisions I've made.

I think "practice" in the airplane is invaluable but that we should avail ourselves to every possible safety advantage at our disposal. I think that any instrument approach shot in less than VFR conditions should be coupled when flying an airplane that can do that precisely. So hand flying once in VMC is okay, but there are ground rules involved. (More about that in the next section.) I also believe VFR skills need to be sharpened as well, but there are times when this is not appropriate too. If you are flying in a congested airport, or one that you are not familiar with, perhaps practice isn't such a good idea.

Setting up the Ground Rules

Here again your ground rules should be tailored to your operation, aircraft, and people. Here are the ground rules we employ:

- When the weather is below basic VFR minimums, instrument approaches are coupled until in VMC. Yes, we can hand-fly our aircraft to minimums and are required to do so in the simulator. But letting the automation do it doubles the number of humans doing the monitoring.

- When the Pilot Flying (PF) is hand-flying the airplane, the Pilot Monitoring (PM) assumes safety/instructor pilot responsibilities.

- No aircraft systems are disabled at any time for the purpose of "training."

- Stable approach criteria are always followed.

- No pilot will exceed any aircraft limitations.

Empowering the "Safety/Instructor Pilot"

One of the biggest problems with the way most of us exercise our hand-flying skills is that we do so in an incomplete manner. We are exercising our skills while self critiquing silently. The other pilot is expected to keep quiet before, during, and after the practice. We assume this pilot is nothing more than a "Safety Pilot," as is the normal situation, and will only speak up if something becomes unsafe. This deprives the PF of the most important element of practice: critique.

This problem becomes especially noticeable if the PF has a supervisory role or if the PM is in anyway intimidated by the PF. The best way to overcome this problem is with an effective prebrief that lets the PM know that he or she will be fulfilling two roles in the practice to come. First, they are to speak up if things become unsafe or unstable. Second, they are to observe the PF's performance and are expected to provide a critique in an effort to help the PF improve. I'll have an example for both instrument and visual approach practice.

Instrument Skills

When the weather is good we often brief, "this will be a visual approach backed up by the ILS" or something to that effect. This might be the perfect time to brief, "This will be an ILS that I will fly 'heads down' on the needles with you as my safety/instructor pilot. Standard callouts apply as if we were IMC. Do not allow me to deviate more than half a dot on the localizer or glide path at any point; if I do so below VFR minimums, announce that fact and I will go 'heads up' and take over visually. I might be a bit rusty so I am counting on you to keep us safe and help me with my proficiency."

Visual Approach Skills

A CAVU day might also be the perfect time to practice visual approaches without reference to the electrons. Having a good sight picture of a proper glide path and lateral alignment is something we can lose after years of flying the needles. Here again a good prebrief is important. Let the safety/instructor pilot know that you intend to fly the visual approach without the ILS or other instrument approach in view, but that he or she should have them available. For example:

"I will be flying this approach visually and will not look at the ILS as a backup, but am counting on you to keep an eye on me and the instruments to make sure I don't violate our stable approach criteria. Please speak up if it appears I am getting close to doing so."

The Critique: Maximizing Purposeful Practice

Once the aircraft is on the ground and put away, ask the safety/instructor pilot for a full debrief. Encourage the safety/instructor pilot to be frank and react positively to anything said. For example:

"Everything looked great until we got below about 1,500 feet and the winds shifted. We started to go below glide path to about a dot when you noticed and pulled it back. But then our speed decreased almost ten knots. That's when I said something about the approach becoming unstable."

"That was a good call. I need to do a better job of keeping my eyes moving, even when things are looking good. Thanks!"

As professional aviators we tend to adopt the "professional courtesy" of other professions that basically believe: "Though shall not criticize another professional." But improvement is impossible without honest critique and you owe it to yourself to ask for critique. You also owe it to your fellow pilot to provide it.

Your Logbook as a Grade book

Finally, you also need to keep track of your performances, good and bad. This kind of trend monitoring can help you realize what you need to work on for your next simulator and can also help you diagnose problems in the future. Here is a personal example.

About fifteen years ago, while flying a Challenger 604, I got into a series of poor landings that I was unable to figure out. I tended to flare too early but now and then I flared too late. (Ouch!) The other pilots kept quiet and if I ever said anything, they would say "we all have good and bad streaks in us." But I eventually figured out the problem. You see, every airplane I had ever flown before the Challenger had a four or five degree nose up attitude on approach; the nose low attitude of the Challenger required a larger shift in my eyes from the aim point to the end of the runway during the flare. But I figured it out after a bit of a struggle. Two years later, I needed to relearn my lesson. But my written "grade book" made it easier the second time.

7

Analog, digital, or both?

There appear to be two kinds of pilots in accident reports that involve a stick and rudder problem: those who prefer to hand-fly and those who do not. Ignoring the automation during a night flight into a busy airport is a recipe for disaster. Just think of the near calamity of Air Canada 759 at San Francisco. But not having the skills to fly the same approach without automation can be just as deadly. Think of Asiana 214 for another KSFO example.

We owe it to ourselves to keep proficient and practice in the airplane is invaluable. But there is a right and wrong time to do that. And, more importantly, there is a right and wrong way to practice.

8

Postscript: "brick one?"

Don't you just hate it when old Air Force pilots talk in jargon as if everyone has the same set of experiences? I try very hard to avoid that but it has been pointed out I failed with regards to "brick one."

"Brick One" refers to the very first inch of pavement on a runway. I don't know where that comes from, other than I heard it a lot in the Air Force.

References

(Source material)

Bundesstelle für Flugunfallentersuchung (BFU) German Federal Bureau of Aircraft Accident Investigation, BFU EX010-11, Boeing B777-300ER, Singapore Airlines, Munich, 3 November 2011.

Ericsson, Anders, and Pool, Robert, Peak: Secrets from the New Science of Expertise, First Mariner Books, 2016.

Gulfstream GVII-G500 Airplane Flight Manual, GAC-AC-GVII-G500-OPS-0001, Jul 20, 2018

SAFO 17007, Manual Flight Operations Proficiency, 5/4/17, U.S. Department of Transportation.

Technical Order 1C-135(K)A-1, KC-135A Flight Manual, USAF Series, 10 August 1975

Technical Order 1C-135(K)A-1-1, KC-135A Aircraft Flight Manual Appendix I, Performance Data, 15 June 1966, Change 29, 15 November 1975

Technical Order SR-71A-1, SR-71A Aircraft Flight Manual, Unclassified, 15 Aug 1990

Please note: Gulfstream Aerospace Corporation has no affiliation or connection whatsoever with this website, and Gulfstream does not review, endorse, or approve any of the content included on the site. As a result, Gulfstream is not responsible or liable for your use of any materials or information obtained from this site.